T

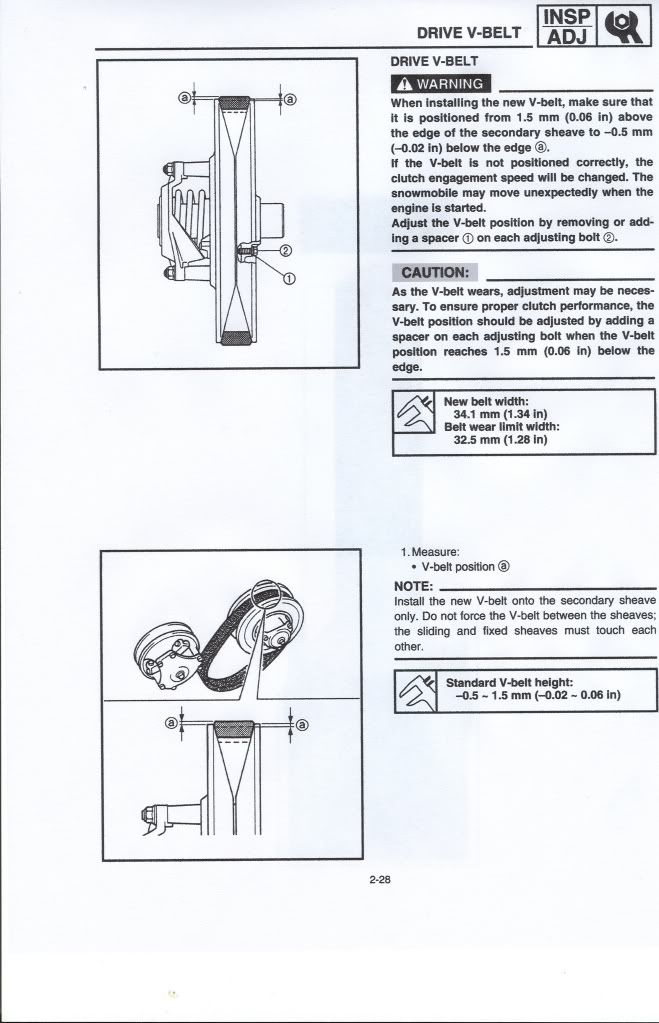

Washers

Where are you guys putting these washers? My belt is also running low in the sec. Shockwave all buttons are good new springs. How much twist on the sec spring? I'm running purple sec. with 78 gram daltons in prime.

Where are you guys putting these washers? My belt is also running low in the sec. Shockwave all buttons are good new springs. How much twist on the sec spring? I'm running purple sec. with 78 gram daltons in prime.