Al, I've seen this argument before... I'll give my point of view here... [IMO]. I present this after talking to the people at Camoplast, and other respected people in the field like Jack Struthers.

An OVER-tightened track I

S counter productive to performance as you say... not to pe confused with a Properly tightened track.

Since the weight of the sled presses the track against the hyfax (in use, compared to on the stand) the 'loosness' in a loose track has to happen some where... the track

does balloon at the top unless the track is unloaded or catches some air.

As much as the track is pulled on the top by the driver, it is "pushed" past the hyfax on the bottom.

The physics of a track and tension / take-up are NOT the same as a chain drive under load. In a sled, the track is what transfers the power to the ground... not transferring power to something else that transfers the power (like in a motorcyle with the sprocket/tire being driven).

With a loose track... the tunnel side of the track cycles thru a herky-jerky motion of going from banjo-string tight to ballooning out as you run with the inherrent loading and undloading of the drivetrain that a sled goes thru in accelleration, dealing with terrain and braking... even more exagerated by the large amount of weight that you added with the studs on your semi-long track ripsaw.

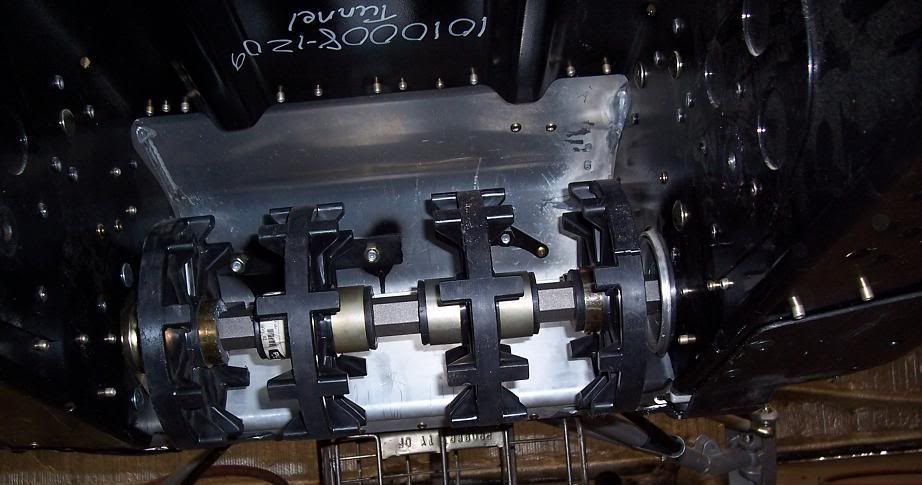

As you point out a properly adjusted track DOES rely on the track being pulled past the rear ider. A looser track cant do this all the time and this is what causes the problems... the loosness in the track has to go somewhere... that somewhere ends up being the distortion of the track as it is crammed past the hyfax or gets tripped up in the drivetrain. This distortion of the track lays the paddles down and tilts the clips on edge which can also accellerate hyfax wear.

As the track leaves the driver, a loose track will get bunched up at the front of the rail... in that situation the rails must strip the loose track from the driver and Force the track down along the rail/hyfax... A loose track does not get "pulled" around the rear idler like a properly tensioned track does.

In this age of single ply tracks, seen mostly on the mountain sleds, the belting of the track is not a rigid as a multi ply track.. they are even more susceptible to this bunching-up of the track as it leaves the drivers.

When the track bunches up between the driver and rail.. this is where the 'stabbing' occurs.

A ripsaw is a 2.52" pitch track (unless it is the 'lite" version at 2.86" pitch). These are much more rigid tracks to start with and much shorter.

I'm curious, If you don't like pow snow and only ride groomer/hardpack... why the longer 136" track? Also, since you are not concerned with weight... I would imagine that you have 8 or 10 bogie wheels along the skid too???

The best analogy of the bunching up that I can think of of is kind of like watching a drag racing tire "wrinkle" as it launches... not a direct analogy... but something that shows the kind of hook-up that a sled with good traction is getting.

I run a 155" to 159" track, NO bogie wheels, standard Hyfax and Avid Drivers with trimmed rails. I run the Polaris Factory prescribed tension on the track. I have yet to stab a track or wear out a set of hyfax during the season but I do replace them long before they are needed at the beginning of each season. I have yet to see or hear about a 2008/09 Polaris IQR with standard combo-toothed drivers and short rail tips stabbing a track... and boy do they punish those sleds!

I have also never smoked a bearing on a driveshaft, but I have replaced them as part of PM on sleds over 2500 miles to protect my ride time on the sled... none of the drive shaft bearings removed on the end or in the case have ever been worn out. I have had jackshaft bearings go on me though, but have since switched out to a greasable PTO side setup and hope for better results there.

IMO, if a loose track gave better performance... the factory race teams would be running that on the snowcrossers and oval track sleds. In this never ending game of trying to outdo each other, the factories would not leave something as easy to fix on the table...again IMO.