Well, I hope it still works now that im done this project!! lol Lots of time chasing wires end to end. no lights, no sensors, no nothing, just regulated power feeding the ecu and a tach input (hurray for fixed timing curve). dess key, reverse button and kill switch are all that are left. gonna replace with new wires the right length for final install!!

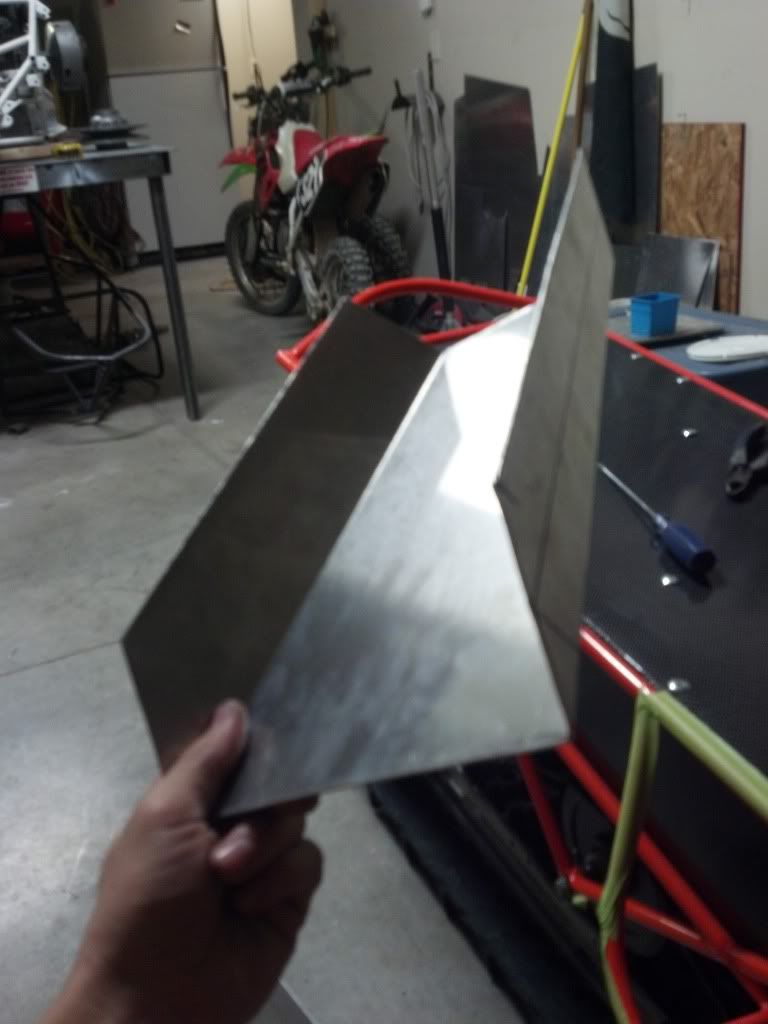

this is the WHOLE wiring harness. now all i do is tap into my main 12v DC wire to hook up my accsories. still some little parts to clean but its mostly done.

this is the WHOLE wiring harness. now all i do is tap into my main 12v DC wire to hook up my accsories. still some little parts to clean but its mostly done.