Someone definitely should do a How to thread on doing the top end, I would like to do mine before I turbo

For what it's worth, Ill throw out what I learned. I took a few pics along the way, and it's fresh in my mind.

Start by removing:

-side panels

-hood

-console

-over-structure

-oil bottle/clutch cover

-upper air intake duct

I left the coils, and VES solenoid attached to the over-structure, just cut some zip ties and disconnect the wiring.

Have a bolt ready to plug the oil hose when you disconnect it from the bottle, almost zero mess if you are quick.

Next I dealt with the fuel system.

Disconnect the hoses at the tank, and removed the 2 bolts securing the fuel rail to the cylinder block. There are also 2 alen head bolts that hsecure the injector wiring to the throttle body to remove. The rail pulls out easily, but as mentioned above... keep a close check on the green o-rings that will likely stay in the cylinder ports but could easily get away from you. The TPS wiring is tangled up with the injector wiring so you will have to cut some more zip ties. In this pic below, you can see one of the 2 bolts that secure the fuel rail to the cylinder block.

Coolant draining.

This is best done with a wet/dry shop vac. I disconnected the upper hose from the thermostat housing first. I jam the end of the shop vac hose into the coolant hose, and then remove the thermostat housing, and the thermostat itself. The shop vac will suck out almost everything. There is also a small coolant hose from the throttle body to the head that must be disconnected.

Now you are free to remove the head cover, head and cylinders. This is as straight forward as it gets. Use a rubber mallet to free the parts once the bolts are removed. There are 2 cylinder locating dowels at each rear outside corner.

As you can see I chose to strip the y-pipe, VES and such on the bench. I wont go into detail here, it's the same parts polaris has been using for years, very basic to work on. It's obviously a good time to cean the VES system, and check the bellows. I did not have the proper hone, so I farmed it out to a buddy who does.

Here are some pics I took of wiring and hose routing "just in case"

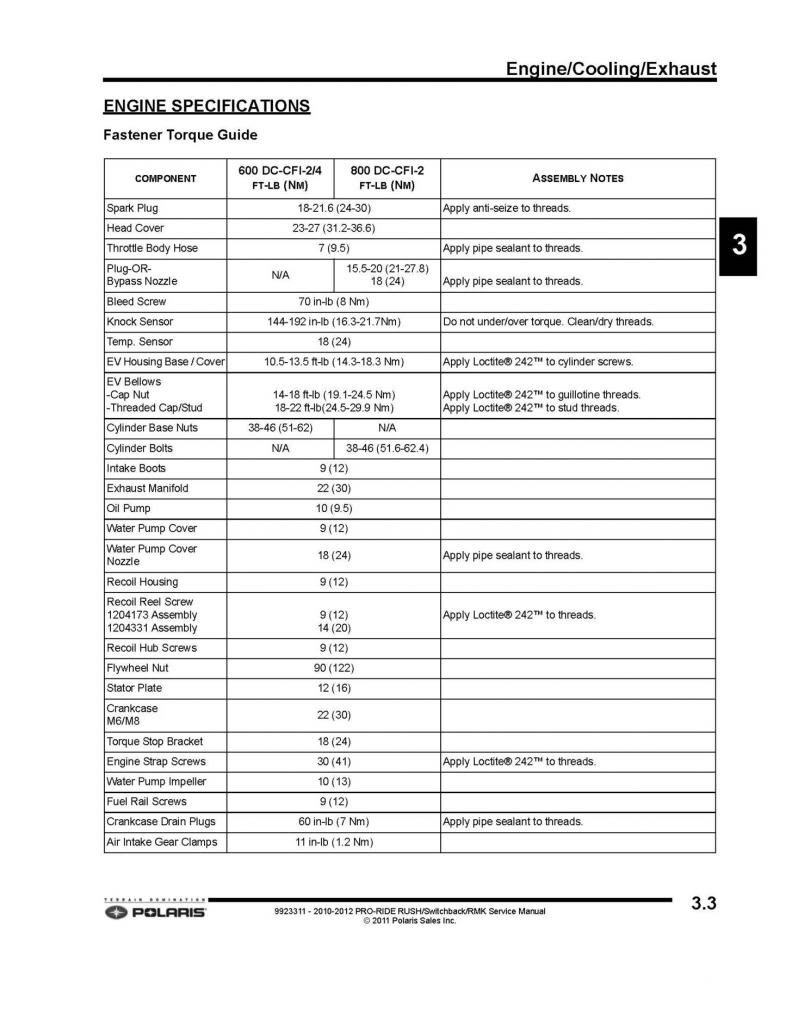

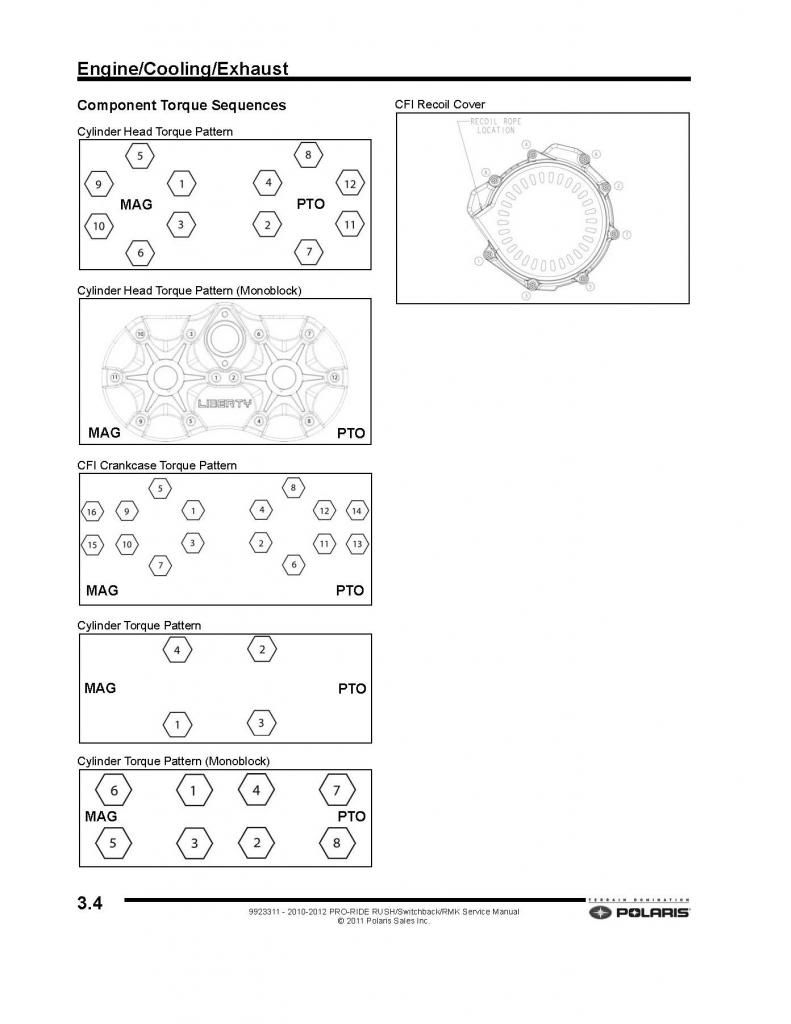

These are from an older manual, 2012 if I remember right:

I'm sure I left alot out, so feel free to add to this info, or correct me if I messed up on something.

Dan