S

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Another NyPro Project

- Thread starter sportsterdanne

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

S

S

S

S

S

S

S

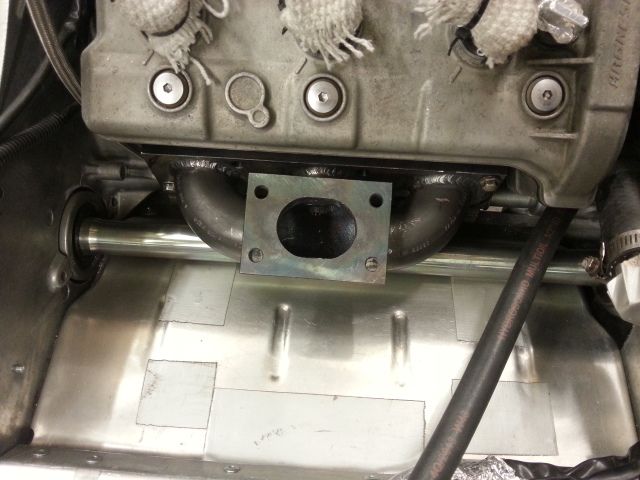

Modified the fuel inlet i cant have it to the rear because of the exhaust and in the front the plenum.

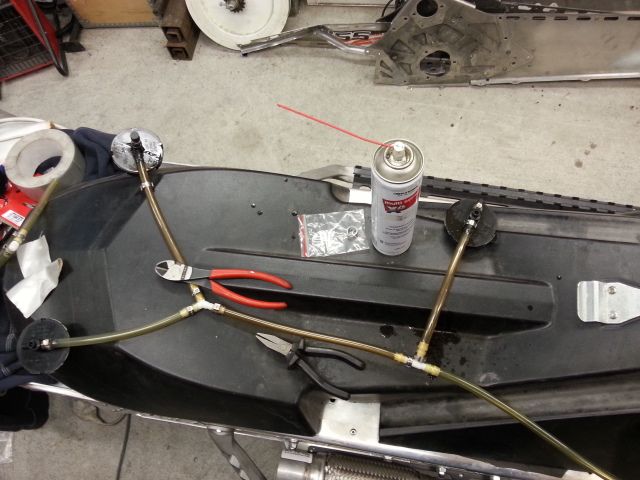

Made a adapter to attach the heads vent to the oiltank vent hose instead of a separate hose all the way to the Catch can.

Modified the filler cap.

Used a straight hose, i will try to find a transparant hose to see the coolant level.

Installed locking pins on the front of clutch cover, also secured them with som wire.

Made a adapter to attach the heads vent to the oiltank vent hose instead of a separate hose all the way to the Catch can.

Modified the filler cap.

Used a straight hose, i will try to find a transparant hose to see the coolant level.

Installed locking pins on the front of clutch cover, also secured them with som wire.

S

J

That Should work just fine. Good work!

Very nice!

Side note. A little scale removal goes a long way when tig welding cast elbows.

Less train tracks ( undercut )

They look like standard forged pipe fittings to me (not cast, few to no pipe fittings are cast these days other than ductile iron or cast iron, neither would be used here and neither would look like those), but agree with proper prep being key to a good weld. Most all qualified weld procedures require a minimum of one inch cleaned on each side of the weld.

Carry on!

S

Thanks for the heads up. Ill make sure to remove more scale in the future, im a rookie at Tig welding and appreciate all advice !

S

S

S

S

S

My friend helped me mill the flanges and then i sandblasted it.

Some header paint.

I also picked up my sheets of 6082 T6 alu for the tunnel. did some testing on a scrap piece and was able to bend two 45 degree angles pretty close to each other and it looks ok (could not find anyone that could bend it with a radius)

Some header paint.

I also picked up my sheets of 6082 T6 alu for the tunnel. did some testing on a scrap piece and was able to bend two 45 degree angles pretty close to each other and it looks ok (could not find anyone that could bend it with a radius)

S

Some parts has arrived.

Flexpipe.

45 degree hose and header wrap.

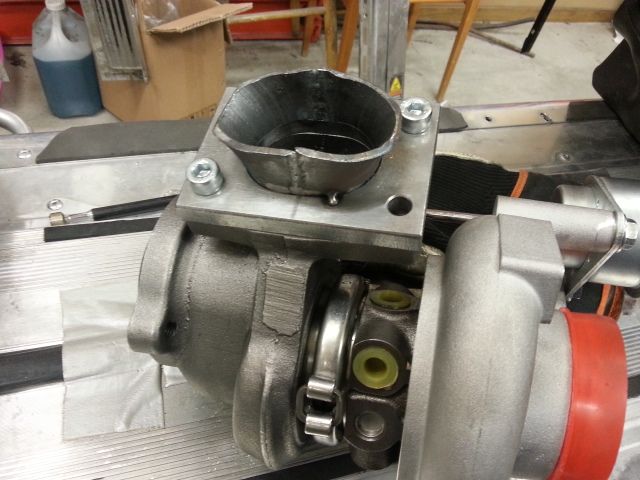

Modified the right side to get some more clearance, i ordered a Cobra elbow to the intake side on the turbo.

did some more welding on the intake, installed a 25mm tube for the BOV and a 16mm tube for the smaller hose.

Modified the stock heat shield.

Flexpipe.

45 degree hose and header wrap.

Modified the right side to get some more clearance, i ordered a Cobra elbow to the intake side on the turbo.

did some more welding on the intake, installed a 25mm tube for the BOV and a 16mm tube for the smaller hose.

Modified the stock heat shield.

Similar threads

T

- Replies

- 1

- Views

- 2K

T

- Replies

- 24

- Views

- 5K

H

- Replies

- 16

- Views

- 2K

C

M

- Replies

- 0

- Views

- 2K

M