might as well start another project.

picked this up, boosted it, made it most of the year, then t-boned a tree at WOT.

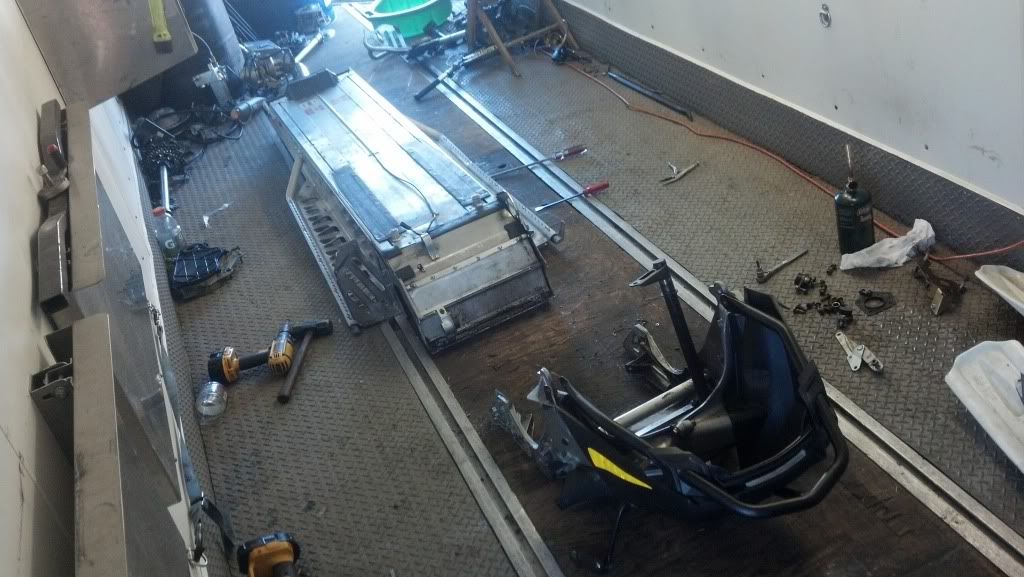

DAMAGE

straightened it out, then put it on the rocks

the track was rubbing, and the rocks vandalized the running board

time for rework

picked this up, boosted it, made it most of the year, then t-boned a tree at WOT.

DAMAGE

straightened it out, then put it on the rocks

the track was rubbing, and the rocks vandalized the running board

time for rework