Happened to mine last January

https://www.dootalk.com/forums/topic/1486906-850-missingstumbling/?p=22571803

The bare wires touched each other, grounding out, malfunctioning the auxiliary injector.

The wires in the picture are now stripped, ready to pull the wire prongs out of the plug to remove and replace the original wire back onto the prongs. Then put the ty-raps in a different location to prevent vibration chafing.

I also posted this Apr 25th last season

https://www.dootalk.com/forums/topic/1536602-a-complete-miss-when-idleing/?p=22066121

I have had the check engine light come on twice this season.

First episode was the wiring harness going to the PTO fuel injector plug on the throttle body. Mechanic had snip the tyraps off at the plug, then cut the wires from the plug. Cut the worn-through wires off and stripped the wire ends. Pulled the prongs out of the injector plug and re-fastened them to new stripped wire ends. Shoved the prongs back in the plug - Secondary injector started to work again.

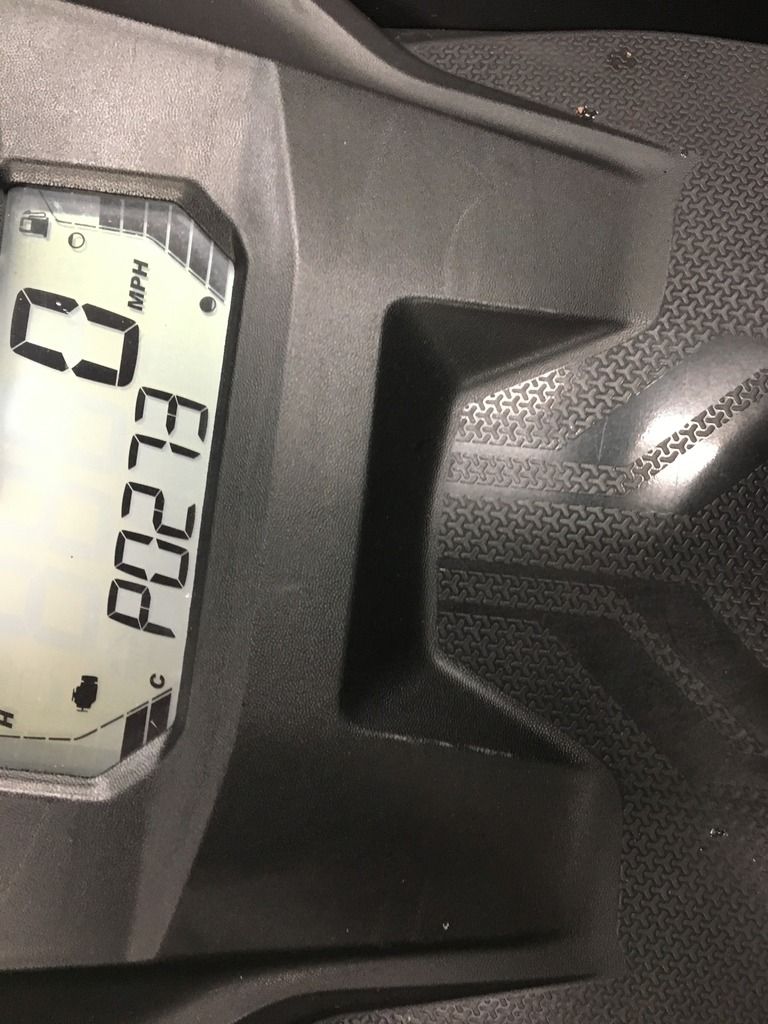

Second episode recently; My dash was beeping "check engine" and the coolant temperature gage on the left side was going blank. The whole left side of the dash screen was blanking out, repeatedly as long as I was going through bumps. If i rode the sled slowly on a flat surface, check engine light would go away; gage works again. Start going through bumps; again left side of screen shuts off - no idiot lights. I had the temperature gage running on the middle of the screen and the temperature would bounce from 40c to 55c to -40 to -44, then "check engine" (This is the second 2017 sled the mechanic has experienced the same "feature"...haha). He pulled the airbox to get to some wires on the ECU and they were worn through bare. Snipped the wires, made mechanical connections with them. My sled runs good again. Dash working.

Both situations the "zip strip" or "Ty-raps" were tight enough they were squeezing the wires and the vibration from the sled running chafed the insulation coating right off the wires.

My mechanic friend has been telling his experiences on the private corporate BRP "mechanics" forum where mechanics go to talk about how to resolve problems. I bet your local BRP mechanic might be able to identify your facts, finding them on their forum too.