So.

Now that I am finally getting close to actually INSTALLING these things after months of very slowly getting the sled prepped, I am wondering about the 0.75 inch lip that Skinz had me cut for the boards to rest on.

As you can see from the photo there is more than just a little of that lip protruding under the main tube that rests against the tunnel wall, and I am wondering just how much of that I can safely trim back???

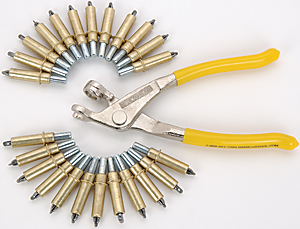

While I am not there yet, my guess is the Rivets are the reason they want the extra metal left hanging there, but I am really not sure yet.

As I said earlier, my plan is to epoxy the boards to the tunnel first, then drill, then rivet them with the expectation that the epoxy will add a "Lot" of additional structural integrity and stiffness to the whole system.

Now that I am finally getting close to actually INSTALLING these things after months of very slowly getting the sled prepped, I am wondering about the 0.75 inch lip that Skinz had me cut for the boards to rest on.

As you can see from the photo there is more than just a little of that lip protruding under the main tube that rests against the tunnel wall, and I am wondering just how much of that I can safely trim back???

While I am not there yet, my guess is the Rivets are the reason they want the extra metal left hanging there, but I am really not sure yet.

As I said earlier, my plan is to epoxy the boards to the tunnel first, then drill, then rivet them with the expectation that the epoxy will add a "Lot" of additional structural integrity and stiffness to the whole system.