Starting on a sled for my kids to ride because Polaris wont make a light weight mid size sled that goes thru powder. This wont be mid size but I hope to get it down bellow 400 Lbs. My daughter will be 10 this year and the 120 is just to small wont work in powder and she is getting to big to put in front of me when we go in the back country.

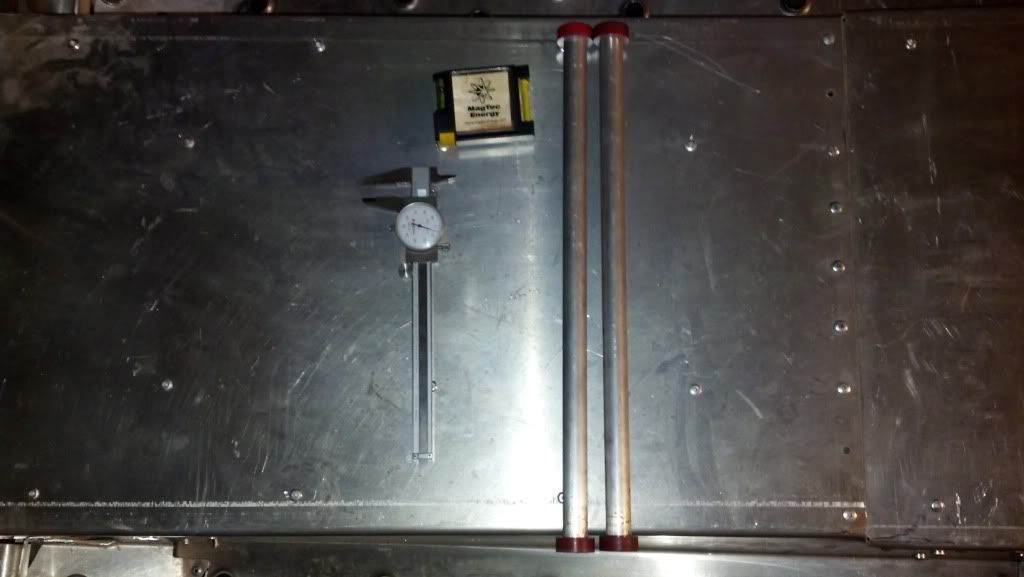

Starting with a 2006 CMX that I bought as a roller. The 151 track and M10 is out and will be replaced with a 2013 Polaris skid that will be shortened to 141 with a 141 X 1.6 Cobra track. Have a 440 Polaris fan engine from a donor sled. The Coolers are out and I have some Burant boards that I am trying to make work. Here are some picks of the mods needed to make some NOS 141 rails work.

Starting with a 2006 CMX that I bought as a roller. The 151 track and M10 is out and will be replaced with a 2013 Polaris skid that will be shortened to 141 with a 141 X 1.6 Cobra track. Have a 440 Polaris fan engine from a donor sled. The Coolers are out and I have some Burant boards that I am trying to make work. Here are some picks of the mods needed to make some NOS 141 rails work.