K

First build thread can be found here:

http://www.ty4stroke.com/threads/another-pro-nytro.116477/

Version two will be a tube chassis mounted to the pro rmk bulkhead. a lot of this idea has came from jskattum606's propex build. Planning on using the stock clutches and getting custom jackshaft and driveshaft from http://www.industrialjigandfixture.com/ and building a belt drive setup instead of a chaincase.

I think the biggest problem with the nytro is the high center of gravity. so far I have a drawing in cad and the top of the new fuel tank is lower than the top of the nytro tunnel!!!! Should be a drastic improvement. Keeping the stock location of the driveshaft relative to the suspension mounting points of my cat float skid.

First I had to build a table to get the sled up on and take some measurments.

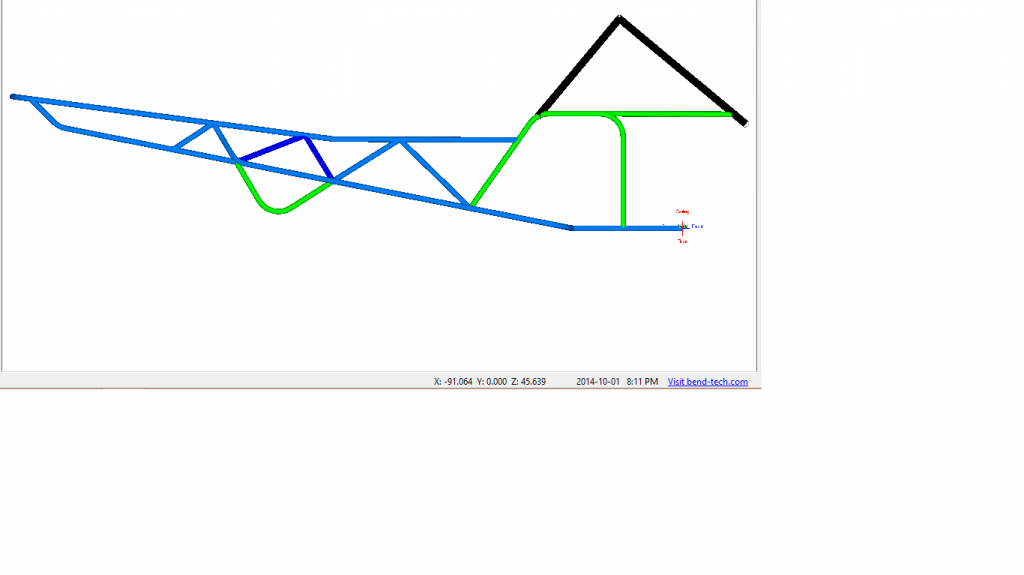

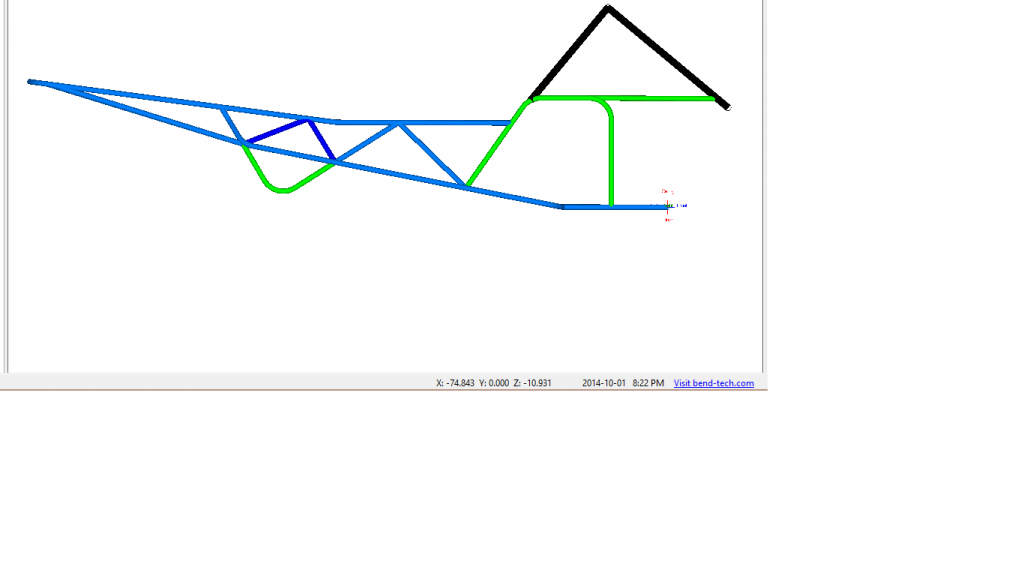

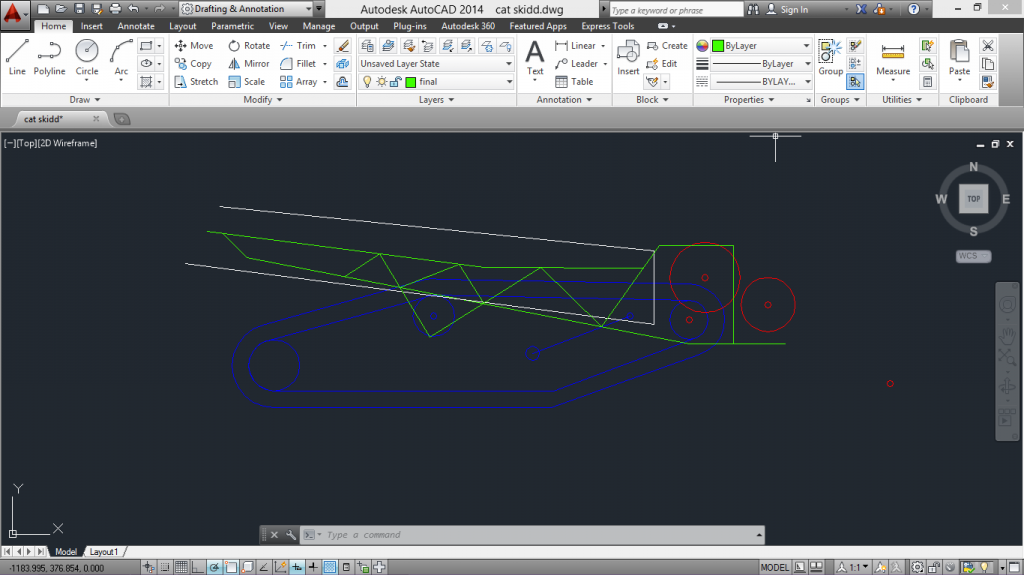

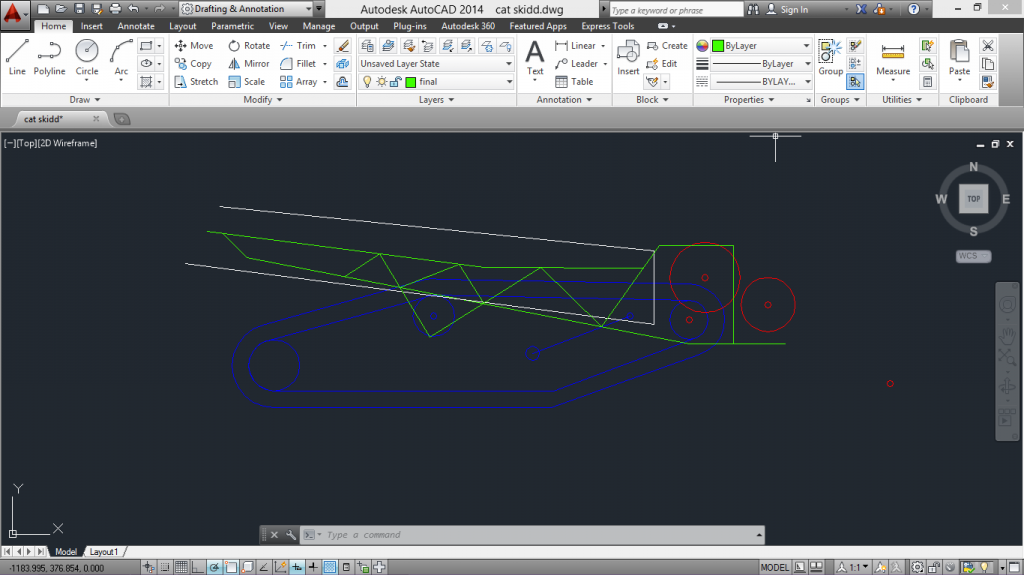

Then transferred into cad and came up with this:

White lines are the old tunnel, green the new tunnel. hoping to make a fuel tank that is only about 5" tall and keep the center of gravity low.

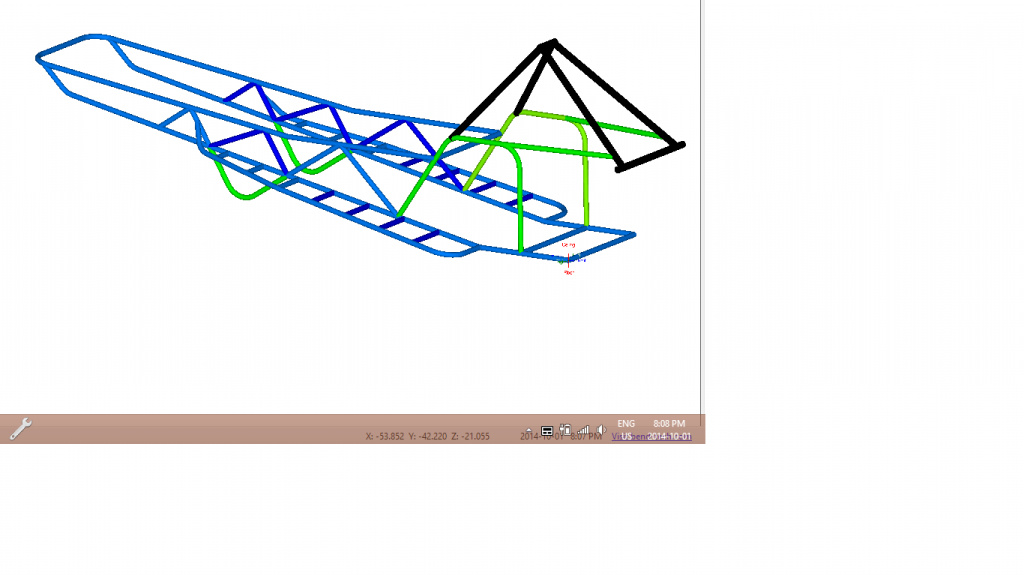

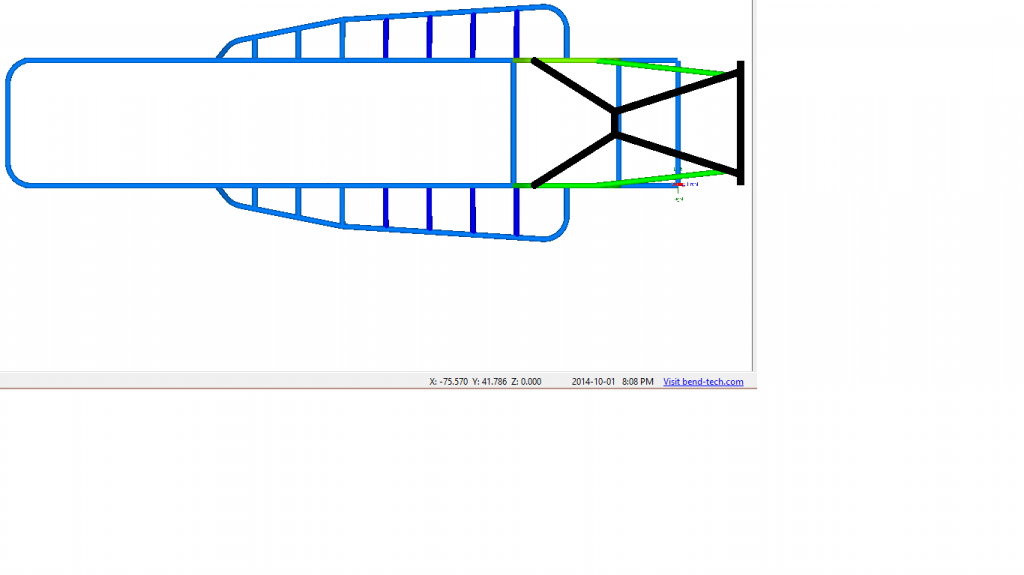

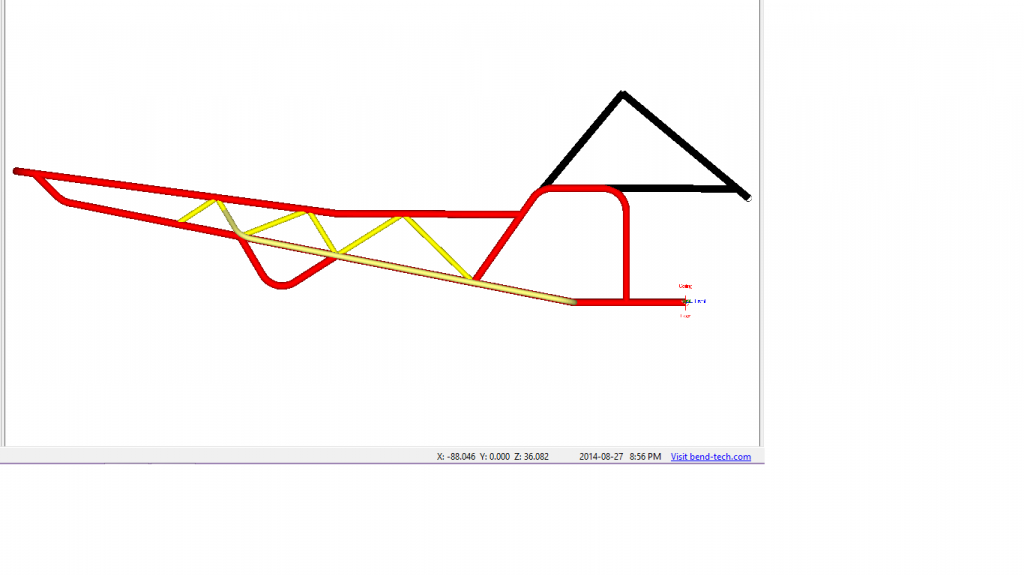

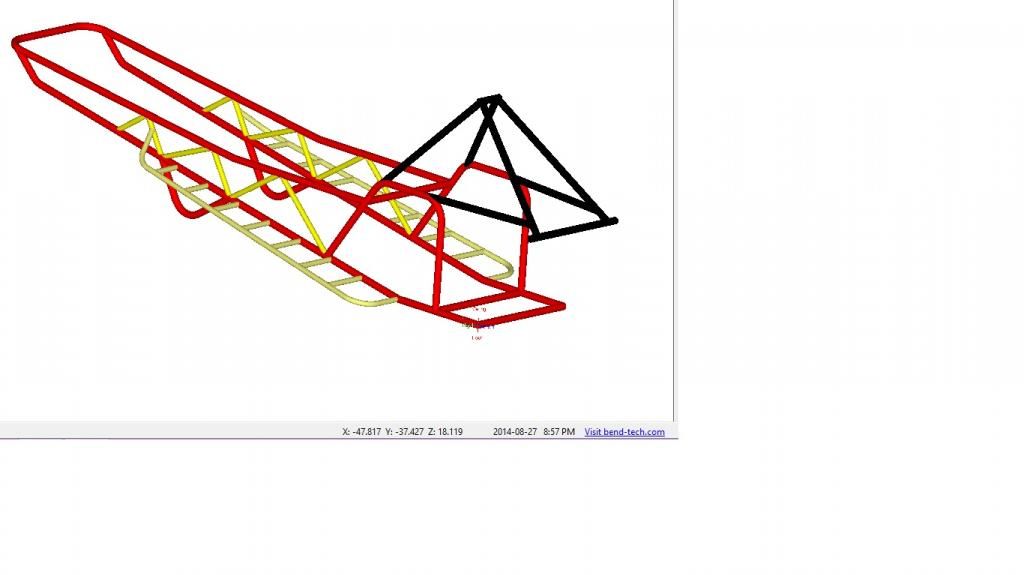

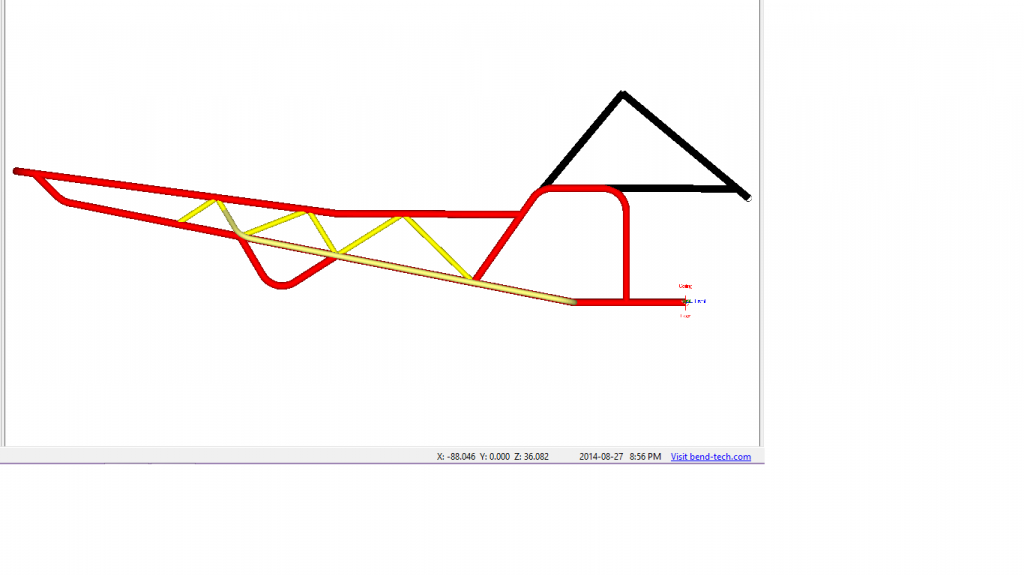

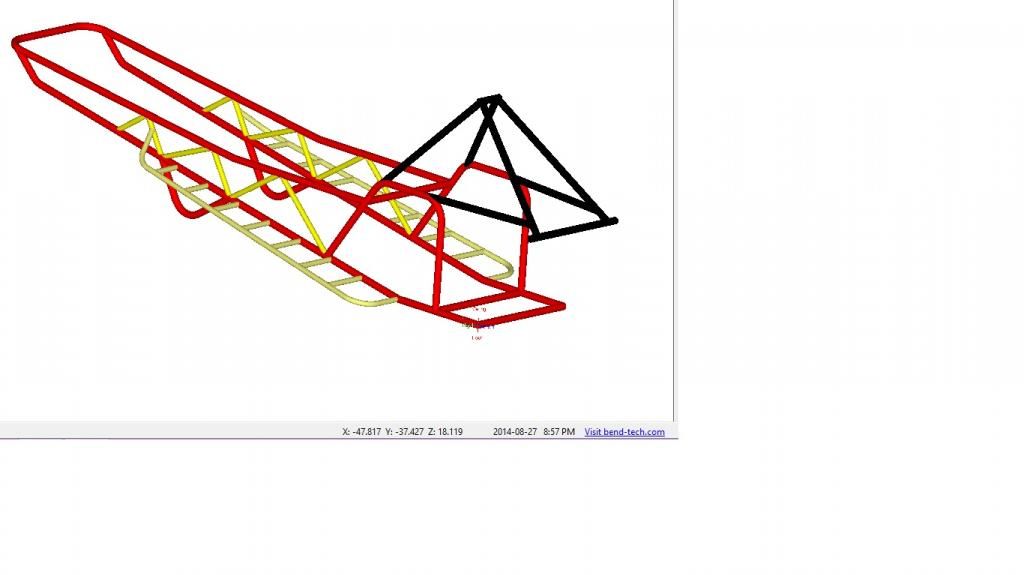

Now drawn in Bend Tech.

so far most of the tube is 1" .065 wich is probably overkill. Currently weighs 38lbs according to bend tech. changing the tunnel to 3/4" .035 takes the chassis down to 22 lbs.

http://www.ty4stroke.com/threads/another-pro-nytro.116477/

Version two will be a tube chassis mounted to the pro rmk bulkhead. a lot of this idea has came from jskattum606's propex build. Planning on using the stock clutches and getting custom jackshaft and driveshaft from http://www.industrialjigandfixture.com/ and building a belt drive setup instead of a chaincase.

I think the biggest problem with the nytro is the high center of gravity. so far I have a drawing in cad and the top of the new fuel tank is lower than the top of the nytro tunnel!!!! Should be a drastic improvement. Keeping the stock location of the driveshaft relative to the suspension mounting points of my cat float skid.

First I had to build a table to get the sled up on and take some measurments.

Then transferred into cad and came up with this:

White lines are the old tunnel, green the new tunnel. hoping to make a fuel tank that is only about 5" tall and keep the center of gravity low.

Now drawn in Bend Tech.

so far most of the tube is 1" .065 wich is probably overkill. Currently weighs 38lbs according to bend tech. changing the tunnel to 3/4" .035 takes the chassis down to 22 lbs.