Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Tips for getting driven clutch apart

- Thread starter rmscustom

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

R

I'm amazed that so many find this a difficult issue. Heat them up, melt the locktite, then a couple of blows on an impact driver (like shown above) and they come out easy. You can even use a cheap bit if you get the bolt good and hot. No biggie at all. I started removing them and other similar fasteners years ago and I can say I have never had to drill or grind one out or off.

I thought the same before this one. Didn't appear to be any lock tite on the bolts either.

O

I suspect many guys don't heat them up and then use an air impact wrench and tear crap up.

O

I thought the same before this one. Didn't appear to be any lock tite on the bolts either.

I haven't found anything unique about these fasteners or their application. I have always found one type of Loctite or another used. If heated... HOT most melts off and that's the issue. Don't use anti seize just some blue Loctite and torque to spec.

I'm amazed that so many find this a difficult issue. Heat them up, melt the locktite, then a couple of blows on an impact driver (like shown above) and they come out easy. You can even use a cheap bit if you get the bolt good and hot. No biggie at all. I started removing them and other similar fasteners years ago and I can say I have never had to drill or grind one out or off.

Some of us aren't as lucky as you. We don't walk on water...

C

When going back together, try not to give them the "gorilla" when snugging back down. They seem to come out easier later.

YES. 13 ft. lbs. is not very much!!! Just a quick hand torque with a 1/4" drive ratchet has never let me down. Haven't had to use a torch once and have never had one come loose without wanting it to.

A good quality torx bit is helpful. The key is to make sure the bit is pushed all the way DOWN into the bolt and fully seated before twisting out. Its kind of a three-hand job because you basically need one to hold the clutch from spinning, one to turn the ratchet, and one to push the bit down into the bolt the entire time. Without the downward force you just don't get a good bite and it will chew itself up in no time.

$6 a piece? Really?

If I remember right I think they had blue loctite on them.:face-icon-small-con I stopped at Ske's Snowmobile Parts, and he gave me a set. $.00. People buy the helix but don't ask for the bolts, so he has extras laying around. I guess if there is a sled salvage area close by, call them.

http://www.skessnowmobileparts.com/

http://mohawksalvage.net/

If I remember right I think they had blue loctite on them.:face-icon-small-con I stopped at Ske's Snowmobile Parts, and he gave me a set. $.00. People buy the helix but don't ask for the bolts, so he has extras laying around. I guess if there is a sled salvage area close by, call them.

http://www.skessnowmobileparts.com/

http://mohawksalvage.net/

R

I suspect many guys don't heat them up and then use an air impact wrench and tear crap up.

Didn't even touch em without heat first. After heating I tried a little with a ratchet (usually always works for me after heat) and it was a no go and went straight to the manual impact. Hit it with a 18v cordless 1/4" impact after nothing else worked but that was pointless.

Think these would hold up better?

http://www.pesidaho.com/shop/titanium-secondary-clutch-kit-polaris

http://www.pesidaho.com/shop/titanium-secondary-clutch-kit-polaris

R

YES. 13 ft. lbs. is not very much!!! Just a quick hand torque with a 1/4" drive ratchet has never let me down. Haven't had to use a torch once and have never had one come loose without wanting it to.

A good quality torx bit is helpful. The key is to make sure the bit is pushed all the way DOWN into the bolt and fully seated before twisting out. Its kind of a three-hand job because you basically need one to hold the clutch from spinning, one to turn the ratchet, and one to push the bit down into the bolt the entire time. Without the downward force you just don't get a good bite and it will chew itself up in no time.

You can make it a two handed job by locking the brake and putting the clutch back on the jackshaft backwards

O

Some of us aren't as lucky as you. We don't walk on water...

Dave must be having a bad day. LOL

There are numerous things that gives me fits, but this isn't one of them. I'm sorry Dave if that fact makes you feel inferior.

Last edited:

O

You can make it a two handed job by locking the brake and putting the clutch back on the jackshaft backwards

That's a good idea. I use a bench holder I made, but if you don't have one, I would do the above.

The factory and WPS get a lot of money for these screws and often have to order them in. (about $3.50 each... ouch!)

McMaster Carr has a good alternative... $12 for a box of 50 (life time supply) and a few bucks for shipping... They are fast with order processing and stock these things.

CLICK HERE FOR SCREWS

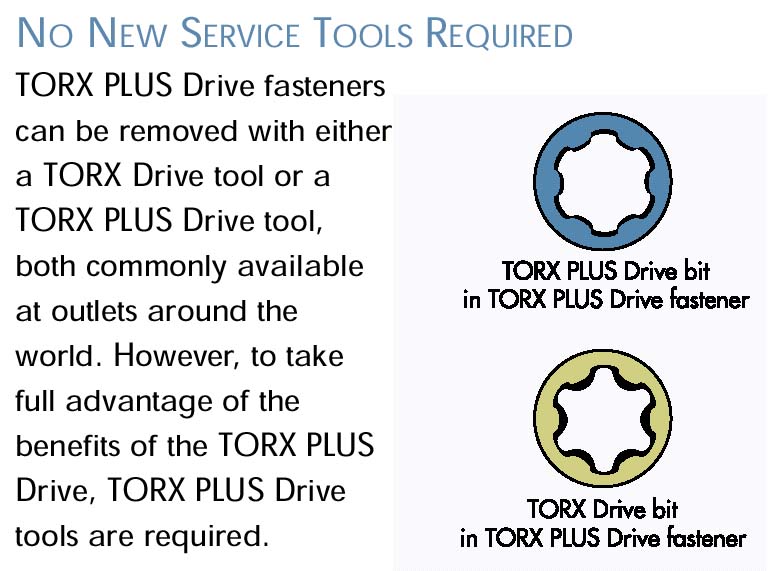

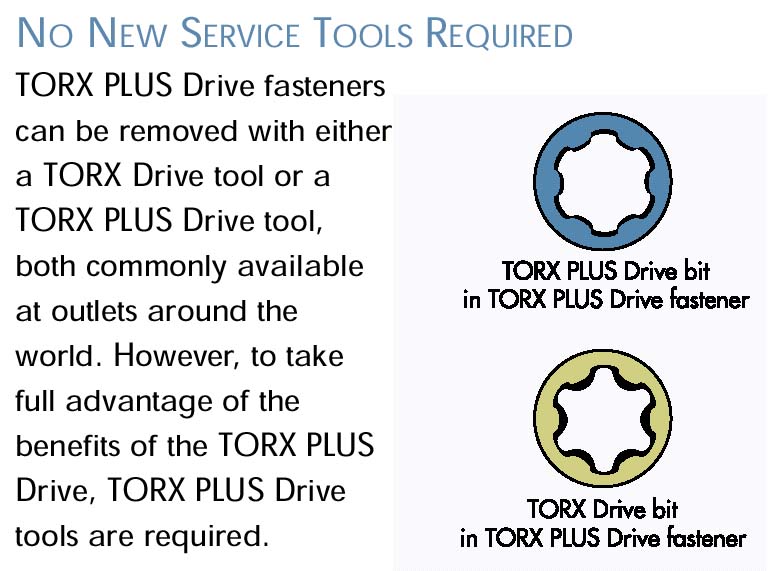

These are TORX-PLUS™ machine screws and will hold up better and resist "cam-out" and stripping of the driver... it is an IP30 Driver.

The only thing is that you have to order a Torx Plus, IP30 bit for these...This is a bigger bit (30 vs 27) and will be better for ya IMO.

http://www.amazon.com/gp/product/B009EK8FX6/

IMO, this bit will be fine and you won't have to go with the super duper snap-on for these (It's a larger drive and the "plus" will take more torque). Snap-on part number though, FTX8TPE. WIHA is a quality German tool mfg.

You still need to use an impact though for good measure.

.

McMaster Carr has a good alternative... $12 for a box of 50 (life time supply) and a few bucks for shipping... They are fast with order processing and stock these things.

CLICK HERE FOR SCREWS

These are TORX-PLUS™ machine screws and will hold up better and resist "cam-out" and stripping of the driver... it is an IP30 Driver.

The only thing is that you have to order a Torx Plus, IP30 bit for these...This is a bigger bit (30 vs 27) and will be better for ya IMO.

http://www.amazon.com/gp/product/B009EK8FX6/

IMO, this bit will be fine and you won't have to go with the super duper snap-on for these (It's a larger drive and the "plus" will take more torque). Snap-on part number though, FTX8TPE. WIHA is a quality German tool mfg.

You still need to use an impact though for good measure.

.

Last edited:

In 2014/2015 Team/Polaris went to a new part number for these screws that has the loctite "pad" already on it... you have to clean that off and use fresh loctite upon reuse.

They are still 1/4-28p x 5/8" fasteners w/T27-drive.

.

They are still 1/4-28p x 5/8" fasteners w/T27-drive.

.

I never put loctite back on them. No problems so far....

When u get a bolt stripped.... set a nut on top of it and put a couple spot welds inside the nut welding it to the torx bolt. I think like a 1/2" nut is what ive used. They spin out like a dream then

When u get a bolt stripped.... set a nut on top of it and put a couple spot welds inside the nut welding it to the torx bolt. I think like a 1/2" nut is what ive used. They spin out like a dream then

Use both cold and heat!

Hi!

My best tip is to put the whole secondary in the freezer for about 30 min. Then heat the bolts with hot air gun.

When the helix makes a poping sound after some minutes of heating it's time to use the impact driver.

that was THE only way for me, had broken several torx bits before that.

Hi!

My best tip is to put the whole secondary in the freezer for about 30 min. Then heat the bolts with hot air gun.

When the helix makes a poping sound after some minutes of heating it's time to use the impact driver.

that was THE only way for me, had broken several torx bits before that.

Thanks Mountainhorse. I just ordered a bag of bolts and a bit. Switching my sled between low altitude and high altitude clutching takes it's toll on those bolts. Usually some heat and a good pop with the impact is all it takes, but I have twisted off my share of Snap-On T-27 bits and have had to resort to welding nuts to the back of the bolts to get them out.

Hoping the Torx Plus is the answer.

Hoping the Torx Plus is the answer.

I got the new IP 30 bolts comming and also put these on the same order

Torx-Plus Bits

Insert

Insert

Power

Power

Designed for use with Torx-Plus screws, these bits provide better torque transfer and torsional strength as well as longer tool life than standard Torx bits. They also reduce stripping.

Note: Bits are not compatible with standard Torx screws.

<TABLE style="MARGIN-RIGHT: 0px" id=RenderableTbl_635548428443709280TMNW class=ItmTbl><THEAD><TR><TH class="ItmTblColSuperHdrAlign PivotHdr"></TH><TH style="PADDING-LEFT: 0px; PADDING-RIGHT: 25px" class="ItmTblColHdrPriceInterior ItmTblColSuperHdrAlign ItmTblColSuperHdrDeflt" colSpan=3>Insert Bits

</TH><TH style="PADDING-LEFT: 0px; PADDING-RIGHT: 5px" class="ItmTblColHdrEndPrice ItmTblColSuperHdrAlign ItmTblColSuperHdrDeflt" colSpan=3>Power Bits

</TH></TR><TR><TD style="PADDING-LEFT: 7px; PADDING-RIGHT: 10px" class="ItmTblBaseHdrBorderCell ItmTblColBaseHdrMinPivotIndent NoWrapCell">Size</TD><TD style="PADDING-LEFT: 0px; PADDING-RIGHT: 10px" class="ItmTblBaseHdrBorderCell ItmTblColBaseHdrSpecInterior NoWrapCell">Lg.</TD><TD style="PADDING-LEFT: 0px; PADDING-RIGHT: 10px" class="ItmTblBaseHdrBorderCell ItmTblColBaseHdr NoWrapCell"></TD><TD style="PADDING-LEFT: 0px; PADDING-RIGHT: 22px" class="ItmTblBaseHdrBorderCell ItmTblColBaseHdrPriceInterior NoWrapCell">Each</TD><TD style="PADDING-LEFT: 0px; PADDING-RIGHT: 10px" class="ItmTblBaseHdrBorderCell ItmTblColBaseHdrSpecInterior NoWrapCell">Lg.</TD><TD style="PADDING-LEFT: 0px; PADDING-RIGHT: 10px" class="ItmTblBaseHdrBorderCell ItmTblColBaseHdr NoWrapCell"></TD><TD style="PADDING-LEFT: 0px; PADDING-RIGHT: 5px" class="ItmTblBaseHdrBorderCell ItmTblColBaseHdrEndPrice NoWrapCell">Each</TD></TR></THEAD><TBODY><TR id=RenderableRow_635548428443709280NZZV><TH colSpan=7>1/4" Hex Shank

</TH></TR><TR><TD style="TEXT-INDENT: 0px; PADDING-LEFT: 7px; PADDING-RIGHT: 15px" class="ItmTblCellIndentPivotMin ItmTblCellSpec ItmTblColSpaceSpec ItmTblContentCell NoWrapCell" data-mcm-prodgrps="1,2">IP30</TD><TD style="TEXT-INDENT: 0px; PADDING-LEFT: 0px; PADDING-RIGHT: 12px" class="ItmTblCellSpec ItmTblColSpaceSpecBefrPartNbr ItmTblContentCell NoWrapCell" data-mcm-prodgrps="1">1"</TD><TD class="ItmTblCellPartNbr ItmTblColSpacePartNbr ItmTblContentCell NoWrapCell" data-mcm-prodgrps="1">54305A25</TD><TD style="PADDING-LEFT: 9px; PADDING-RIGHT: 25px" class="ItmTblCellPrce ItmTblColSpacePrceAftrPartNbr ItmTblColSpacePrceHorizPivotEnd ItmTblContentCell NoWrapCell" data-mcm-prodgrps="1">$2.31</TD><TD style="TEXT-INDENT: 0px; PADDING-LEFT: 0px; PADDING-RIGHT: 12px" class="ItmTblCellSpec ItmTblColSpaceSpecBefrPartNbr ItmTblContentCell NoWrapCell" data-mcm-prodgrps="2">2"</TD><TD class="ItmTblCellPartNbr ItmTblColSpacePartNbr ItmTblContentCell NoWrapCell" data-mcm-prodgrps="2">3716A18</TD><TD style="PADDING-LEFT: 9px; PADDING-RIGHT: 5px" class="ItmTblCellPrce ItmTblColSpacePrceAftrPartNbr ItmTblColSpacePrceTblEnd ItmTblContentCell NoWrapCell" data-mcm-prodgrps="2">$4.86</TD></TR><TR id=RenderableRow_635548428443719280GVHS><TH colSpan=7>5/16" Hex Shank

</TH></TR><TR id=RenderableRow_635548428443909285MGJW><TD style="TEXT-INDENT: 0px; PADDING-LEFT: 7px; PADDING-RIGHT: 15px" class="ItmTblCellIndentPivotMin ItmTblCellSpec ItmTblColSpaceSpec ItmTblContentCell NoWrapCell" data-mcm-prodgrps="1,2">IP30</TD><TD style="TEXT-INDENT: 0px; PADDING-LEFT: 0px; PADDING-RIGHT: 12px" class="ItmTblCellSpec ItmTblColSpaceSpecBefrPartNbr ItmTblContentCell NoWrapCell" data-mcm-prodgrps="1">1 1/4"</TD><TD class="ItmTblCellPartNbr ItmTblColSpacePartNbr ItmTblContentCell NoWrapCell" data-mcm-prodgrps="1">54305A31</TD><TD style="PADDING-LEFT: 9px; PADDING-RIGHT: 25px" class="ItmTblCellPrce ItmTblColSpacePrceAftrPartNbr ItmTblColSpacePrceHorizPivotEnd ItmTblContentCell NoWrapCell" data-mcm-prodgrps="1">6.08</TD><TD style="TEXT-INDENT: 0px; PADDING-LEFT: 0px; PADDING-RIGHT: 12px" class="ItmTblCellSpec ItmTblColSpaceSpecBefrPartNbr ItmTblContentCell ItmTblFiller NoWrapCell" data-mcm-prodgrps="2">__</TD><TD class="ItmTblCellPartNbr ItmTblColSpacePartNbr ItmTblContentCell NoWrapCell ItmTblFiller" data-mcm-prodgrps="2">______</TD><TD style="PADDING-LEFT: 9px; PADDING-RIGHT: 5px" class="ItmTblCellPrce ItmTblColSpacePrceAftrPartNbr ItmTblColSpacePrceTblEnd ItmTblContentCell ItmTblFiller NoWrapCell" data-mcm-prodgrps="2">__</TD></TR></TBODY></TABLE>

Thanks

M H. :face-icon-small-coo!

S/C

Torx-Plus Bits

Designed for use with Torx-Plus screws, these bits provide better torque transfer and torsional strength as well as longer tool life than standard Torx bits. They also reduce stripping.

Note: Bits are not compatible with standard Torx screws.

<TABLE style="MARGIN-RIGHT: 0px" id=RenderableTbl_635548428443709280TMNW class=ItmTbl><THEAD><TR><TH class="ItmTblColSuperHdrAlign PivotHdr"></TH><TH style="PADDING-LEFT: 0px; PADDING-RIGHT: 25px" class="ItmTblColHdrPriceInterior ItmTblColSuperHdrAlign ItmTblColSuperHdrDeflt" colSpan=3>Insert Bits

</TH><TH style="PADDING-LEFT: 0px; PADDING-RIGHT: 5px" class="ItmTblColHdrEndPrice ItmTblColSuperHdrAlign ItmTblColSuperHdrDeflt" colSpan=3>Power Bits

</TH></TR><TR><TD style="PADDING-LEFT: 7px; PADDING-RIGHT: 10px" class="ItmTblBaseHdrBorderCell ItmTblColBaseHdrMinPivotIndent NoWrapCell">Size</TD><TD style="PADDING-LEFT: 0px; PADDING-RIGHT: 10px" class="ItmTblBaseHdrBorderCell ItmTblColBaseHdrSpecInterior NoWrapCell">Lg.</TD><TD style="PADDING-LEFT: 0px; PADDING-RIGHT: 10px" class="ItmTblBaseHdrBorderCell ItmTblColBaseHdr NoWrapCell"></TD><TD style="PADDING-LEFT: 0px; PADDING-RIGHT: 22px" class="ItmTblBaseHdrBorderCell ItmTblColBaseHdrPriceInterior NoWrapCell">Each</TD><TD style="PADDING-LEFT: 0px; PADDING-RIGHT: 10px" class="ItmTblBaseHdrBorderCell ItmTblColBaseHdrSpecInterior NoWrapCell">Lg.</TD><TD style="PADDING-LEFT: 0px; PADDING-RIGHT: 10px" class="ItmTblBaseHdrBorderCell ItmTblColBaseHdr NoWrapCell"></TD><TD style="PADDING-LEFT: 0px; PADDING-RIGHT: 5px" class="ItmTblBaseHdrBorderCell ItmTblColBaseHdrEndPrice NoWrapCell">Each</TD></TR></THEAD><TBODY><TR id=RenderableRow_635548428443709280NZZV><TH colSpan=7>1/4" Hex Shank

</TH></TR><TR><TD style="TEXT-INDENT: 0px; PADDING-LEFT: 7px; PADDING-RIGHT: 15px" class="ItmTblCellIndentPivotMin ItmTblCellSpec ItmTblColSpaceSpec ItmTblContentCell NoWrapCell" data-mcm-prodgrps="1,2">IP30</TD><TD style="TEXT-INDENT: 0px; PADDING-LEFT: 0px; PADDING-RIGHT: 12px" class="ItmTblCellSpec ItmTblColSpaceSpecBefrPartNbr ItmTblContentCell NoWrapCell" data-mcm-prodgrps="1">1"</TD><TD class="ItmTblCellPartNbr ItmTblColSpacePartNbr ItmTblContentCell NoWrapCell" data-mcm-prodgrps="1">54305A25</TD><TD style="PADDING-LEFT: 9px; PADDING-RIGHT: 25px" class="ItmTblCellPrce ItmTblColSpacePrceAftrPartNbr ItmTblColSpacePrceHorizPivotEnd ItmTblContentCell NoWrapCell" data-mcm-prodgrps="1">$2.31</TD><TD style="TEXT-INDENT: 0px; PADDING-LEFT: 0px; PADDING-RIGHT: 12px" class="ItmTblCellSpec ItmTblColSpaceSpecBefrPartNbr ItmTblContentCell NoWrapCell" data-mcm-prodgrps="2">2"</TD><TD class="ItmTblCellPartNbr ItmTblColSpacePartNbr ItmTblContentCell NoWrapCell" data-mcm-prodgrps="2">3716A18</TD><TD style="PADDING-LEFT: 9px; PADDING-RIGHT: 5px" class="ItmTblCellPrce ItmTblColSpacePrceAftrPartNbr ItmTblColSpacePrceTblEnd ItmTblContentCell NoWrapCell" data-mcm-prodgrps="2">$4.86</TD></TR><TR id=RenderableRow_635548428443719280GVHS><TH colSpan=7>5/16" Hex Shank

</TH></TR><TR id=RenderableRow_635548428443909285MGJW><TD style="TEXT-INDENT: 0px; PADDING-LEFT: 7px; PADDING-RIGHT: 15px" class="ItmTblCellIndentPivotMin ItmTblCellSpec ItmTblColSpaceSpec ItmTblContentCell NoWrapCell" data-mcm-prodgrps="1,2">IP30</TD><TD style="TEXT-INDENT: 0px; PADDING-LEFT: 0px; PADDING-RIGHT: 12px" class="ItmTblCellSpec ItmTblColSpaceSpecBefrPartNbr ItmTblContentCell NoWrapCell" data-mcm-prodgrps="1">1 1/4"</TD><TD class="ItmTblCellPartNbr ItmTblColSpacePartNbr ItmTblContentCell NoWrapCell" data-mcm-prodgrps="1">54305A31</TD><TD style="PADDING-LEFT: 9px; PADDING-RIGHT: 25px" class="ItmTblCellPrce ItmTblColSpacePrceAftrPartNbr ItmTblColSpacePrceHorizPivotEnd ItmTblContentCell NoWrapCell" data-mcm-prodgrps="1">6.08</TD><TD style="TEXT-INDENT: 0px; PADDING-LEFT: 0px; PADDING-RIGHT: 12px" class="ItmTblCellSpec ItmTblColSpaceSpecBefrPartNbr ItmTblContentCell ItmTblFiller NoWrapCell" data-mcm-prodgrps="2">__</TD><TD class="ItmTblCellPartNbr ItmTblColSpacePartNbr ItmTblContentCell NoWrapCell ItmTblFiller" data-mcm-prodgrps="2">______</TD><TD style="PADDING-LEFT: 9px; PADDING-RIGHT: 5px" class="ItmTblCellPrce ItmTblColSpacePrceAftrPartNbr ItmTblColSpacePrceTblEnd ItmTblContentCell ItmTblFiller NoWrapCell" data-mcm-prodgrps="2">__</TD></TR></TBODY></TABLE>

Thanks

M H. :face-icon-small-coo!

S/C

Last edited:

McMaster has the bits. 1/4" drive socket type, $7.00 and change.

Sent from my SM-G900V using Tapatalk

Sent from my SM-G900V using Tapatalk

I get that some of you guys use your tools for work and need Snap-On, but I can't pay that much for a tool set that I might not ever use all the sockets. Here is what I bought at Napa. It works, has held up well, and I bought from a local guy that supports our snowmobile club.

By the way, the local Poo dealer charged $5 each for the helix screws! I like MH's idea of buying a box.

Impact tool $34

Torque Set $29

By the way, the local Poo dealer charged $5 each for the helix screws! I like MH's idea of buying a box.

Impact tool $34

Torque Set $29

Similar threads

M

- Replies

- 10

- Views

- 3K

M

- Replies

- 19

- Views

- 913

- Replies

- 11

- Views

- 3K

M