K

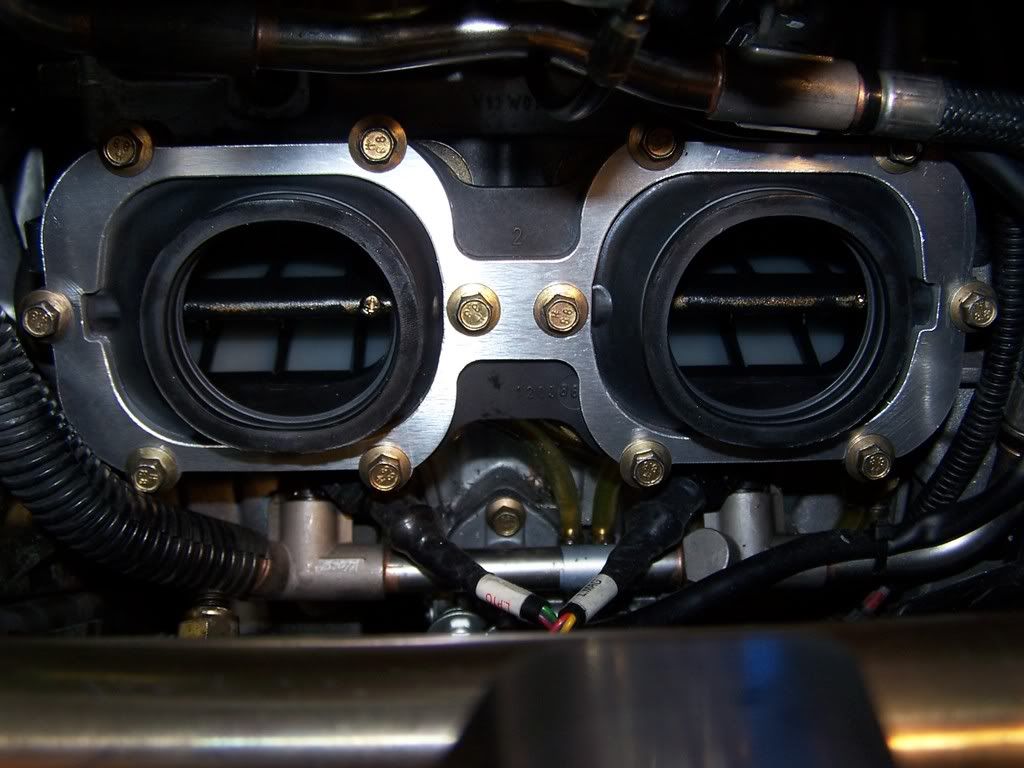

I have a D7 Race gas setup, and one of the problems I encounter is that the throttle body boots delaminate and I lose boost. Anyone else running into this, and more specifically have any tips on how to keep it from happening. I was thinking about machining an sandwich plate out of aluminum, but that would be some serious CNC programming.