E

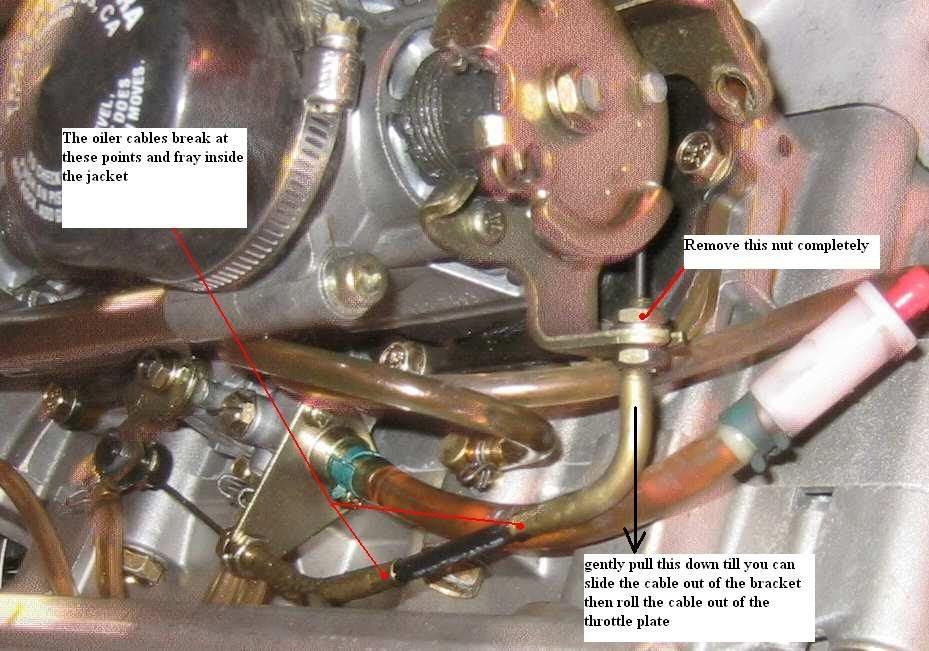

Machine's a 2006 RMK 900 151"... Next project is to replace the throttle body boots as the ones on it now are cracked. Got replacements on order, hopefully they're here by thursday. I looked through the '05 Deep Snow service manual and couldn't find anything real helpful for gettin the TB off then back on again.

The coolant system's drained, did that to remove the front radiator (Kudos to , the eliminator kit came with easy-to-follow directions and it's quality parts). Y-pipe's off, gaskets were leaking and gettin oil everywhere (New gaskets on order as well). Oil hasn't gotten to the stator, sled's performing fine electrically and there's no physical evidence of oil on/near/in it. I think it's just messy but not causing any real damage yet. This will be cleaned up when I get the TB off.

What's the best way to get those boots off and new ones on? Do I need to unhook and remove the TB assembly entirely, or can I just pull it out of the way?

While I'm in there, is there anything I need to look for on the reeds? Sled's got 56hrs/920mi on it... do they need to be cleaned or just looked at? I know the gap needs to be <.015"; I can do that easy enough.

Now for everyone's favorite part:

Cracked PTO-side boot, oil from leaky Y-pipe gasket

The coolant system's drained, did that to remove the front radiator (Kudos to , the eliminator kit came with easy-to-follow directions and it's quality parts). Y-pipe's off, gaskets were leaking and gettin oil everywhere (New gaskets on order as well). Oil hasn't gotten to the stator, sled's performing fine electrically and there's no physical evidence of oil on/near/in it. I think it's just messy but not causing any real damage yet. This will be cleaned up when I get the TB off.

What's the best way to get those boots off and new ones on? Do I need to unhook and remove the TB assembly entirely, or can I just pull it out of the way?

While I'm in there, is there anything I need to look for on the reeds? Sled's got 56hrs/920mi on it... do they need to be cleaned or just looked at? I know the gap needs to be <.015"; I can do that easy enough.

Now for everyone's favorite part:

Cracked PTO-side boot, oil from leaky Y-pipe gasket