J

Got a couple more mods finished up today , and I'll throw in a pic of the finished drop backets from the last round of mods. Moded the tunnel and got my mountain fit vents installed.

I had sagging rails on my running boards so I ran a T6 7/16 rod threw them before building the steps. I used the stock boards to build the steps to keep it looking pretty clean. You can see that I tapered off the tunnel just because I like that look better. I might build a new rear section for the tunnel later on but for now I'll ride it.

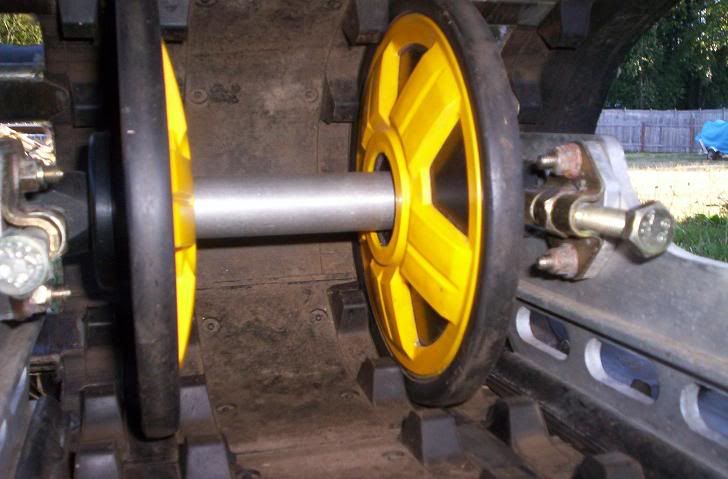

Here are my completed drop brackets, at the top ( just visable threw the hole ) I attached the brackets with two steel rivots, then two 5/16 stainless bolts, and one 3/8 stainless bolt. They are 3/8 thick and should hold up fine. I have them drilled for 1" and 2" drop, I have them droped to 2" and drilled down 1" and back 1/4" up front to keep thing lined up.

I had sagging rails on my running boards so I ran a T6 7/16 rod threw them before building the steps. I used the stock boards to build the steps to keep it looking pretty clean. You can see that I tapered off the tunnel just because I like that look better. I might build a new rear section for the tunnel later on but for now I'll ride it.

Here are my completed drop brackets, at the top ( just visable threw the hole ) I attached the brackets with two steel rivots, then two 5/16 stainless bolts, and one 3/8 stainless bolt. They are 3/8 thick and should hold up fine. I have them drilled for 1" and 2" drop, I have them droped to 2" and drilled down 1" and back 1/4" up front to keep thing lined up.