Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: this_feature_currently_may_not_be_available_in_some_browsers

Installation and Review: Mountain Performance Inc, Stage 1 & 2 Supercharger

- Thread starter christopher

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Thread Rating

- 5.00 star(s)

8

Looks good chris, good job........

This thread is continued here to allow our non-premium members to follow along below the 75 post limit.

http://www.snowestonline.com/forum/showthread.php?p=2768470

http://www.snowestonline.com/forum/showthread.php?p=2768470

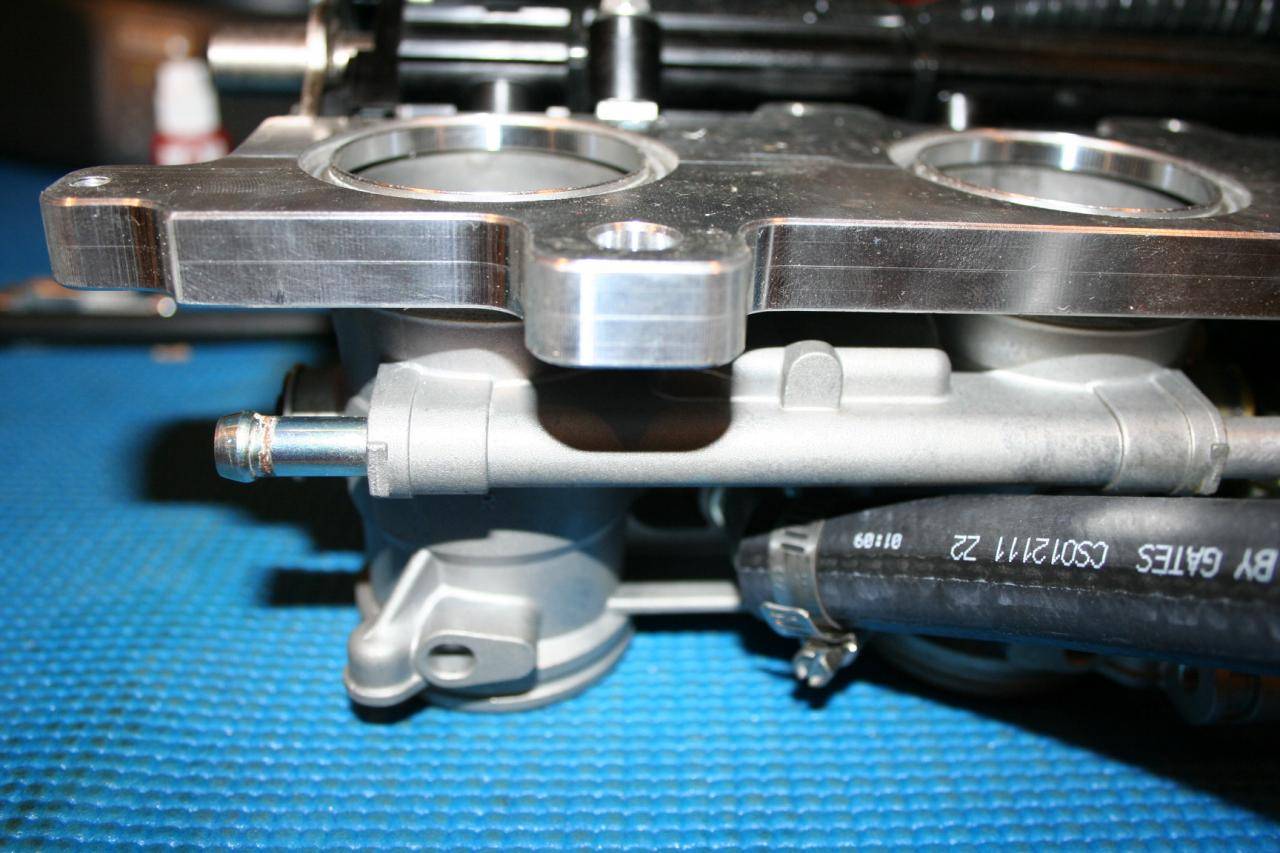

59. Install the New Pressure Manifold included with the kit. This is the Manifold with hoses pre-connected to every port. The outlet points toward the LH side of the vehicle. See Figures 37A, 37B, 37C & 37D.

60. Zip Tie all new connections of the Pressure manifold.

As you can see from this image, some of these hoses seem excessively LONG. I did not trim them as I wasn't sure if there was some compelling reason for their length. But if I had it to do over again, unless told otherwise, I think I would trum the hoses to make a tighter fit as everything fits SO TIGHTLY when it all goes back together again.

60. Zip Tie all new connections of the Pressure manifold.

As you can see from this image, some of these hoses seem excessively LONG. I did not trim them as I wasn't sure if there was some compelling reason for their length. But if I had it to do over again, unless told otherwise, I think I would trum the hoses to make a tighter fit as everything fits SO TIGHTLY when it all goes back together again.

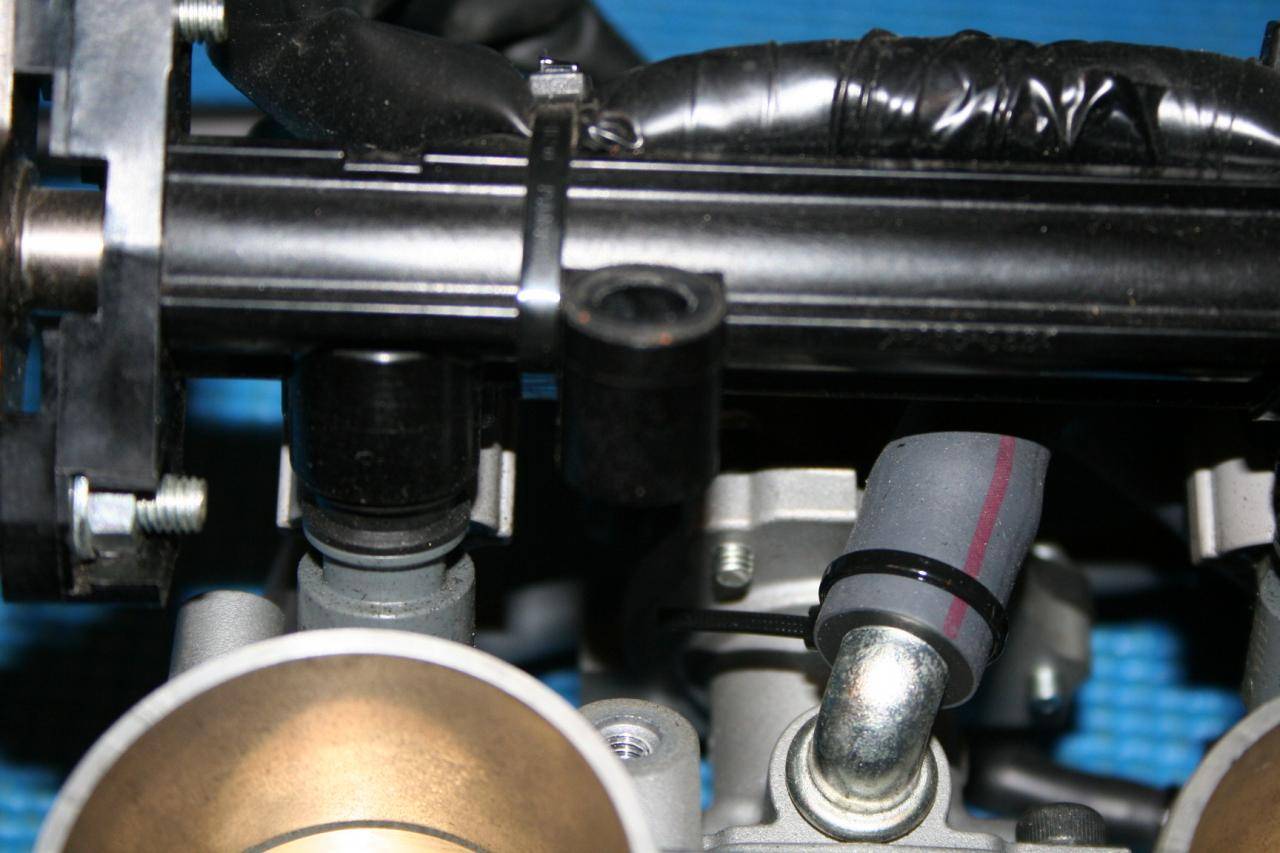

61. Remove the black IAC inlet line with woven fabric from the throttle bodies. See Figure 38.

62. Install the new IAC hose supplied in the kit. This routes to the LH side of the vehicle and will be connected to the LH side of the intercooler in a later step.

This is the hose that has to be removed.

Once the hose has been removed.

The new hose the MPI Supplied.

62. Install the new IAC hose supplied in the kit. This routes to the LH side of the vehicle and will be connected to the LH side of the intercooler in a later step.

This is the hose that has to be removed.

Once the hose has been removed.

The new hose the MPI Supplied.

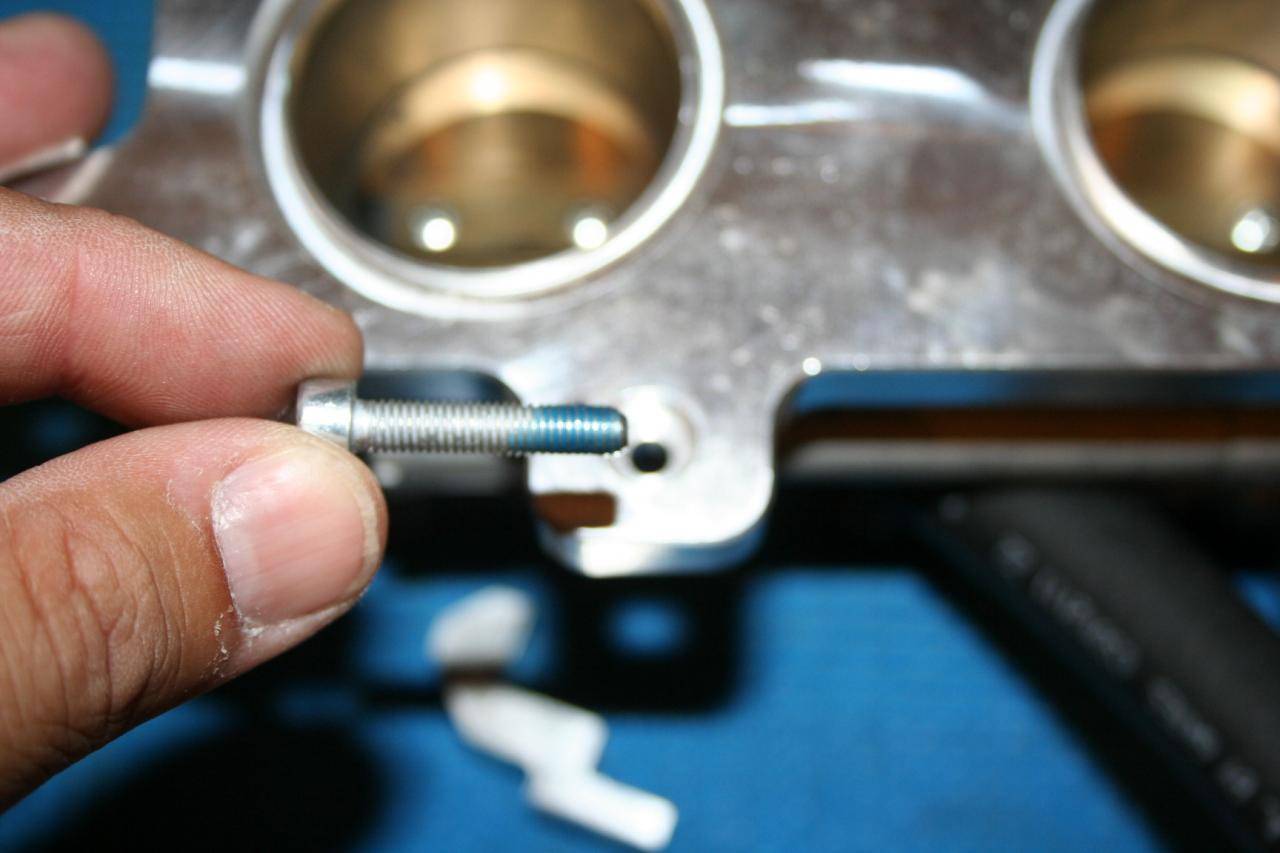

63. Remove the 2 M5 screws holding the fuel rail to the throttle bodies. Remove the 2 cylindrical spacers, YOU DO NOT HAVE TO REMOVE THE FUEL RAIL. Install the supplied throttle body adaptor spacers; install but do not completely tighten the 2 fuel rail screws. This allows for better alignment. See Figure 41.

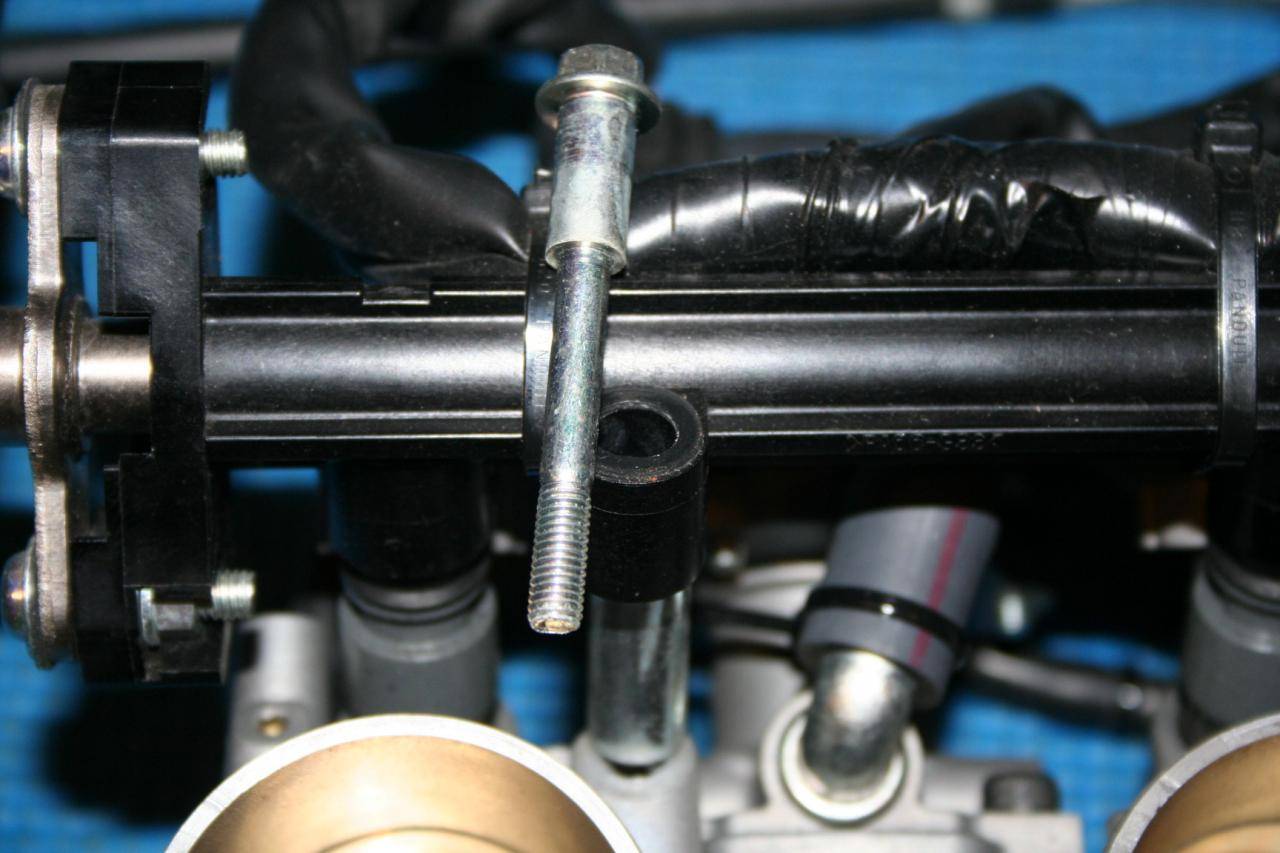

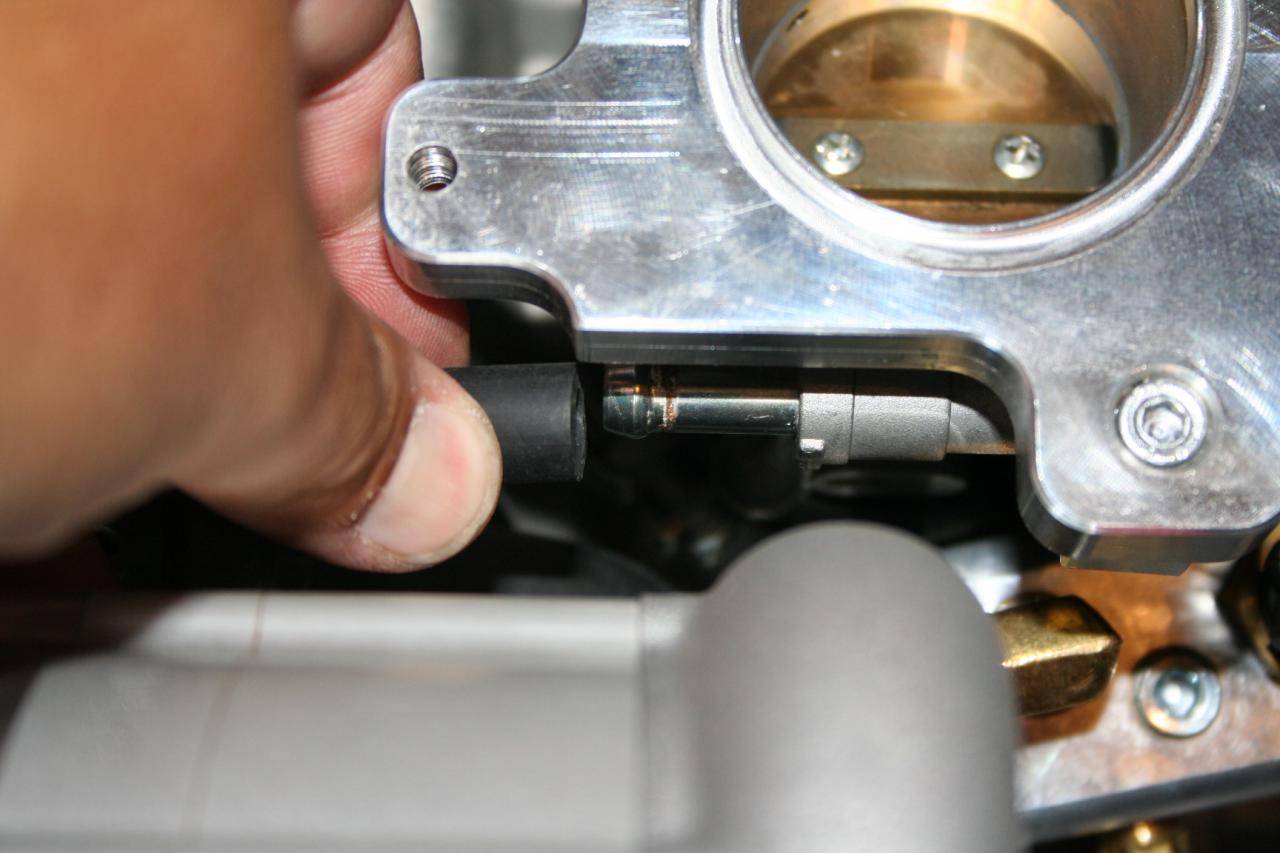

The bolt comes out.

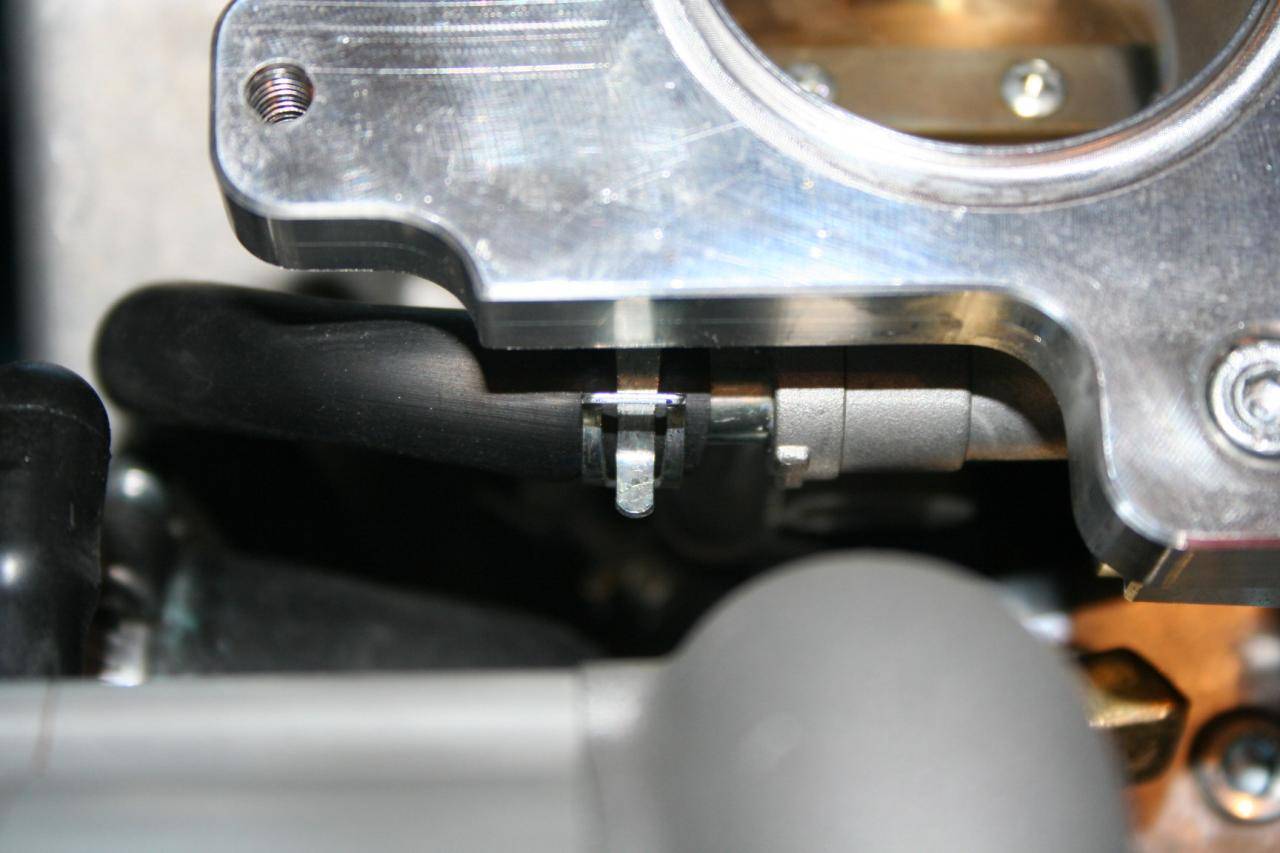

The OEM Cylindrical spacer is removed.

And the new MPI Spacer is inserted.

The bolt comes out.

The OEM Cylindrical spacer is removed.

And the new MPI Spacer is inserted.

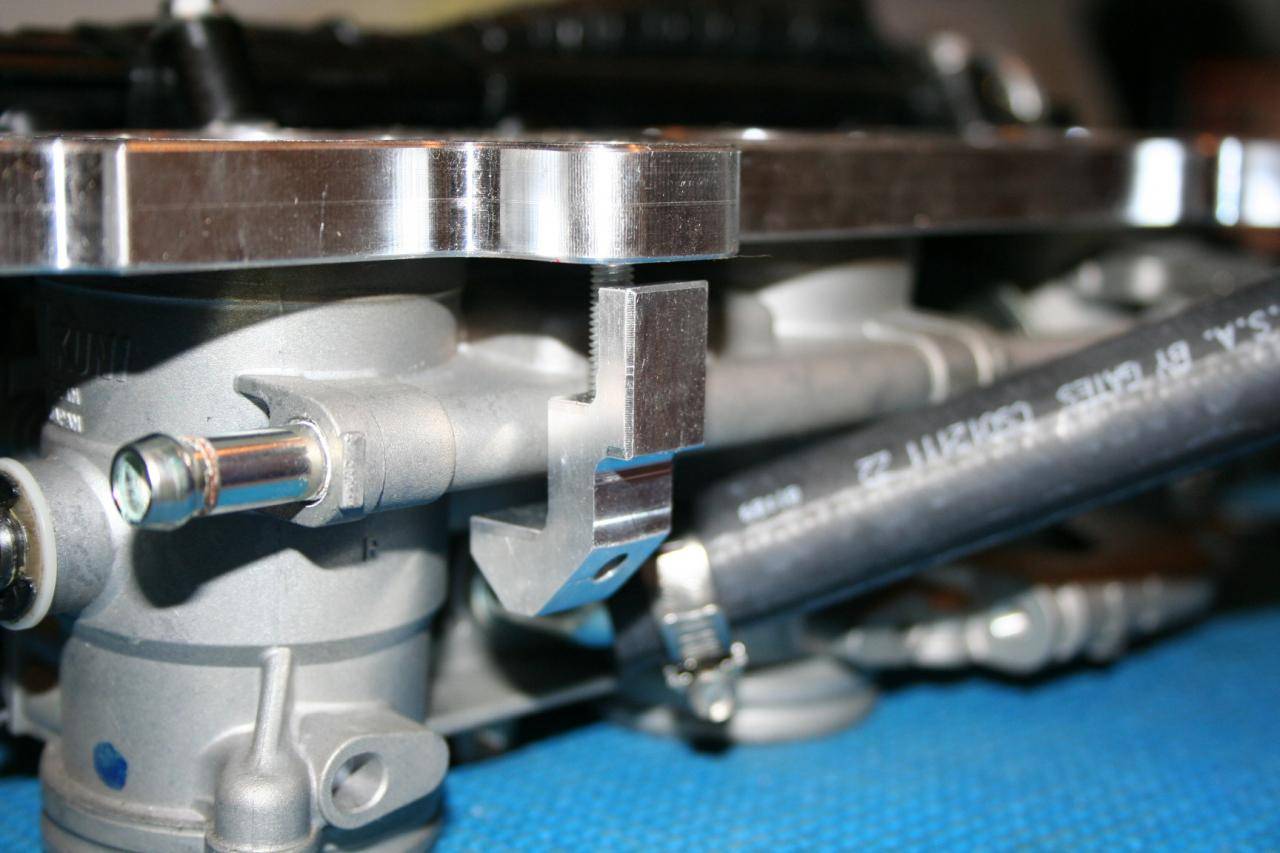

64. Locate the throttle body adaptor plate. Insure that the small diameter o-rings are pre-installed on the underside of the plate. Install the plate and attached it to the spacer brackets you just installed with 2 M5x10 socket head screws. Use blue Loctite, but do not completely tighten yet. See Figure 42.

65. Install the “L” shaped brackets on the front side of the throttle body adaptor plate. Use 2 M5x20 socket head screws. Use blue Loctite. See Figure 42.

66. Tighten the 4 socket head bolts that hold down the throttle body adaptor plate and also tighten the two screws that hold the fuel rail in place.

More Locktite.

The Finished Result.

66. Tighten the 4 socket head bolts that hold down the throttle body adaptor plate and also tighten the two screws that hold the fuel rail in place.

More Locktite.

The Finished Result.

67.5 If you are installing a fuel system upgrade (recommended above 6 PSI at sea-level and above 10 PSI at altitudes above 6000 feet), install the regulator onto the fuel rail now.

68. Install the throttle bodies. It is easier to connect the RH carb heater hose (the 8.5in supplied hose with its other end connected to the water manifold) before you seat the throttle bodies. Also reinstall the throttle cable if you removed it from the throttle bodies earlier. Adjust the cable free play per the OEM service manual.

Note: We recommend leaving the cable attached to the throttle bodies and disconnecting from the thumb trigger.

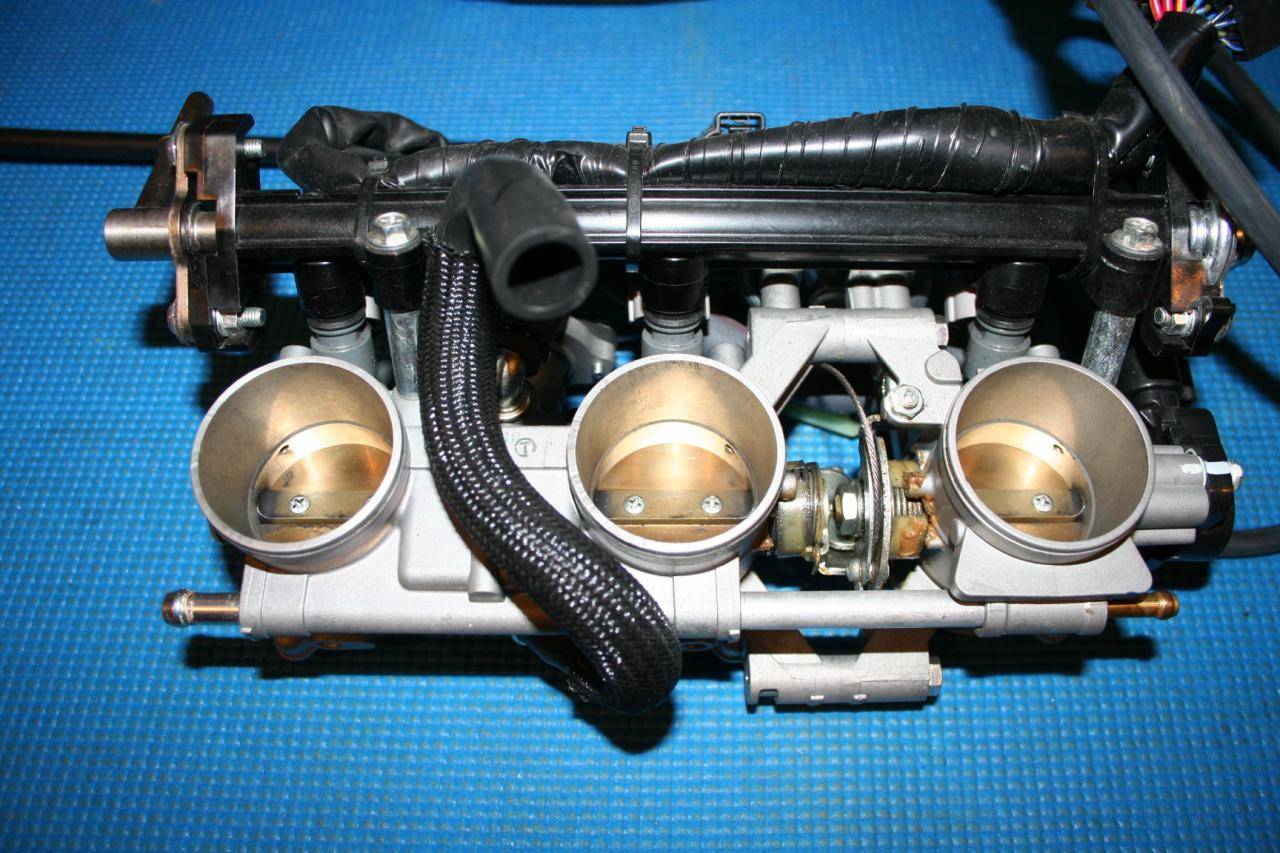

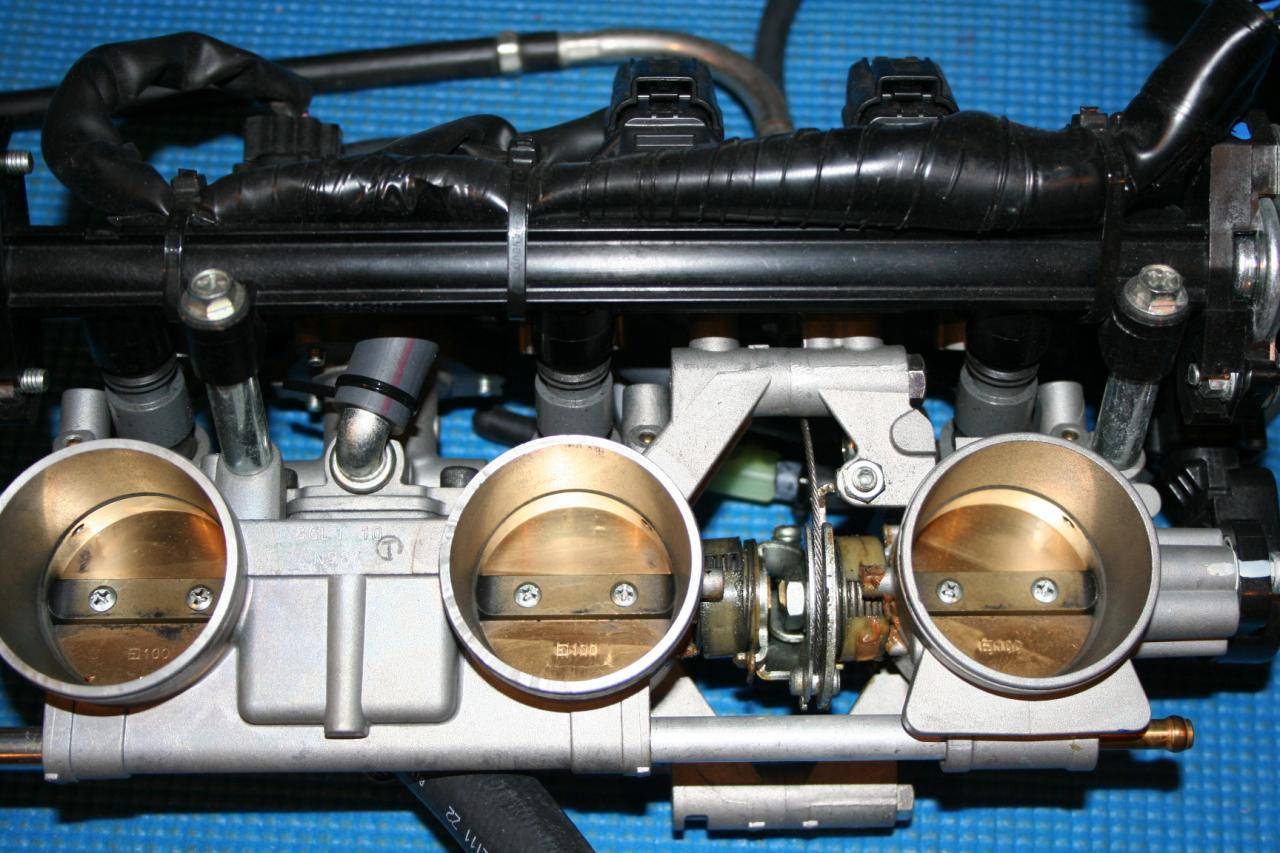

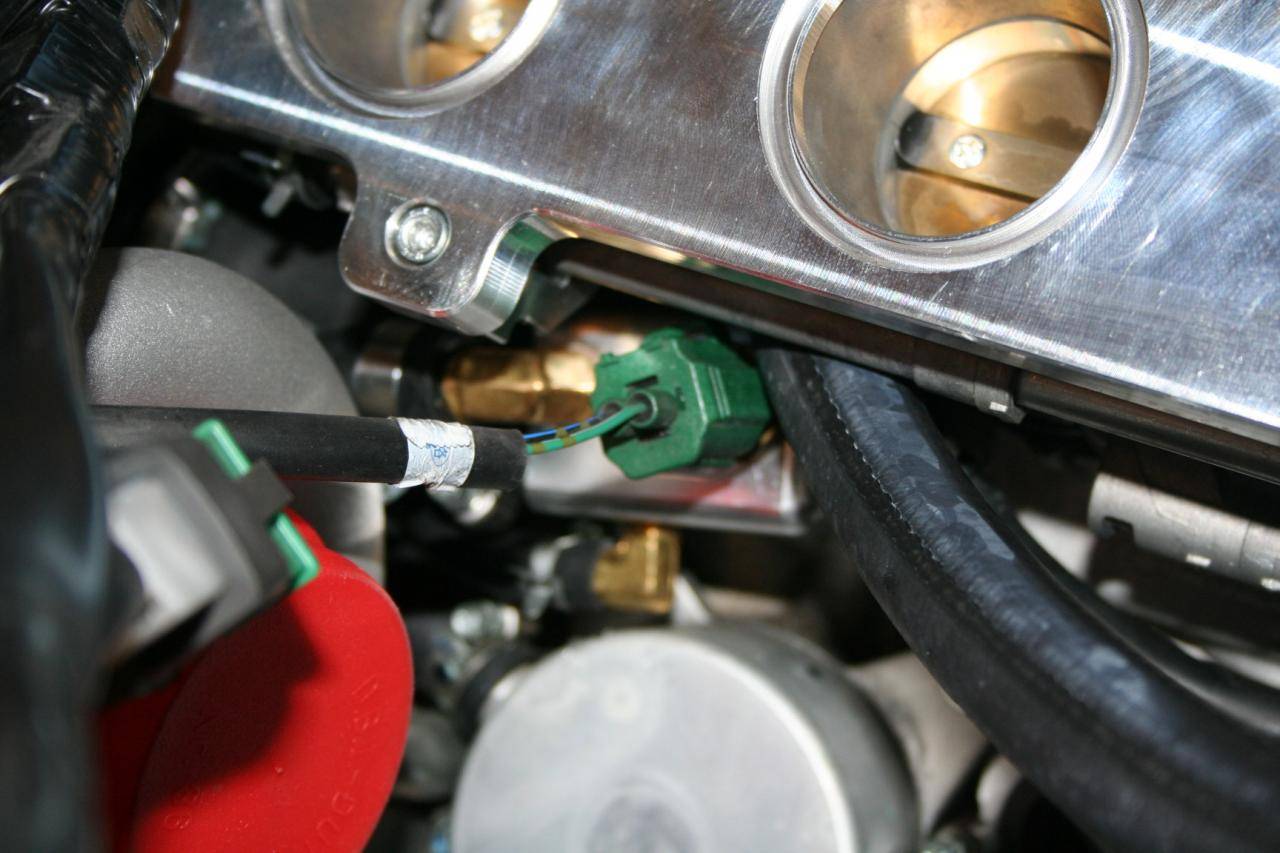

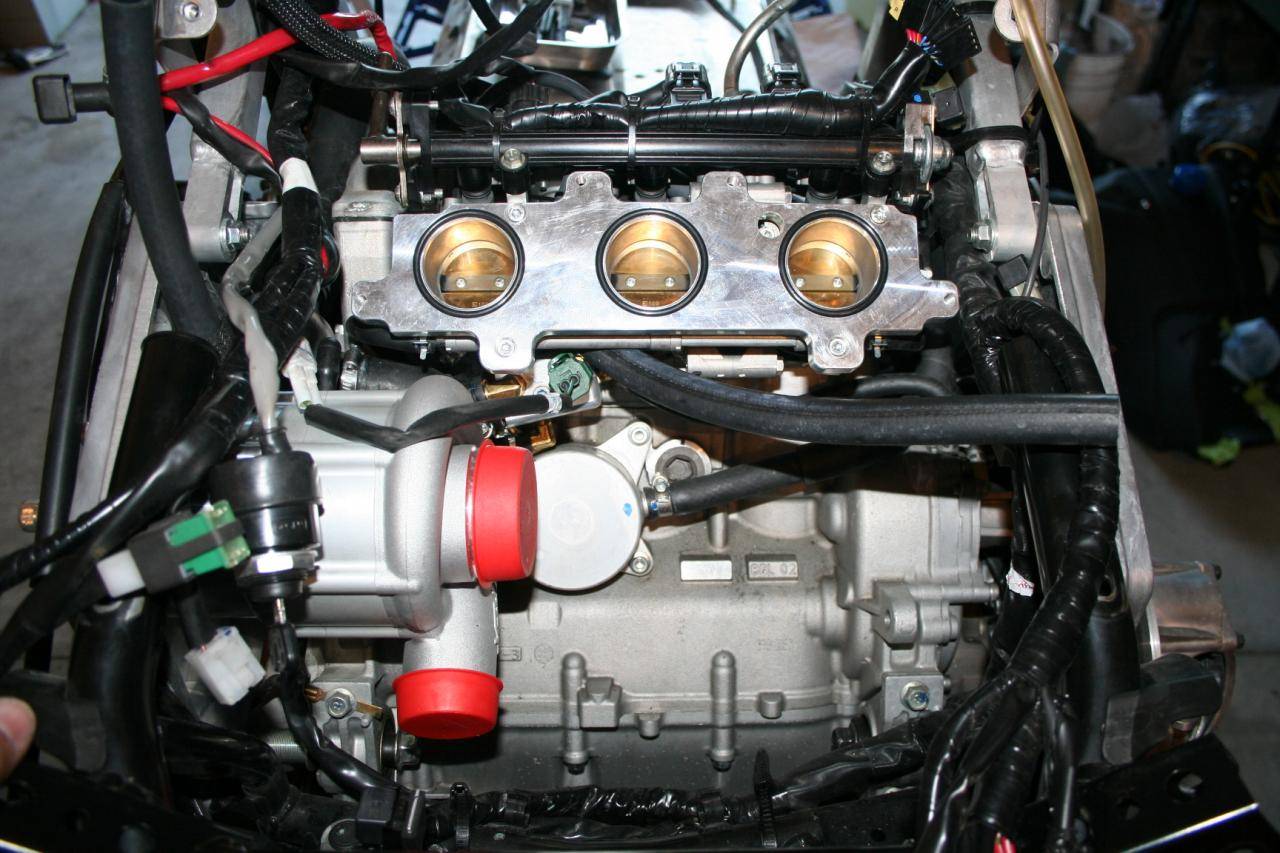

Preparing for the first test fit of the Throttle Bodies.

The RH Carb Heater hose.

One happily attached RH Carb Heater Hose.

And as I lowered the manifold down into the rubber gaskets, I ran into my first problem. The tolerances on this kit are "TIGHT". The hose clamp was pressing up against the Thermostat sending unit.

Once the hose clamp was loosened and rotated back more then it allowed the manifold to drop down onto the rubber gaskets smoothly and without any further interference.

68. Install the throttle bodies. It is easier to connect the RH carb heater hose (the 8.5in supplied hose with its other end connected to the water manifold) before you seat the throttle bodies. Also reinstall the throttle cable if you removed it from the throttle bodies earlier. Adjust the cable free play per the OEM service manual.

Note: We recommend leaving the cable attached to the throttle bodies and disconnecting from the thumb trigger.

Preparing for the first test fit of the Throttle Bodies.

The RH Carb Heater hose.

One happily attached RH Carb Heater Hose.

And as I lowered the manifold down into the rubber gaskets, I ran into my first problem. The tolerances on this kit are "TIGHT". The hose clamp was pressing up against the Thermostat sending unit.

Once the hose clamp was loosened and rotated back more then it allowed the manifold to drop down onto the rubber gaskets smoothly and without any further interference.

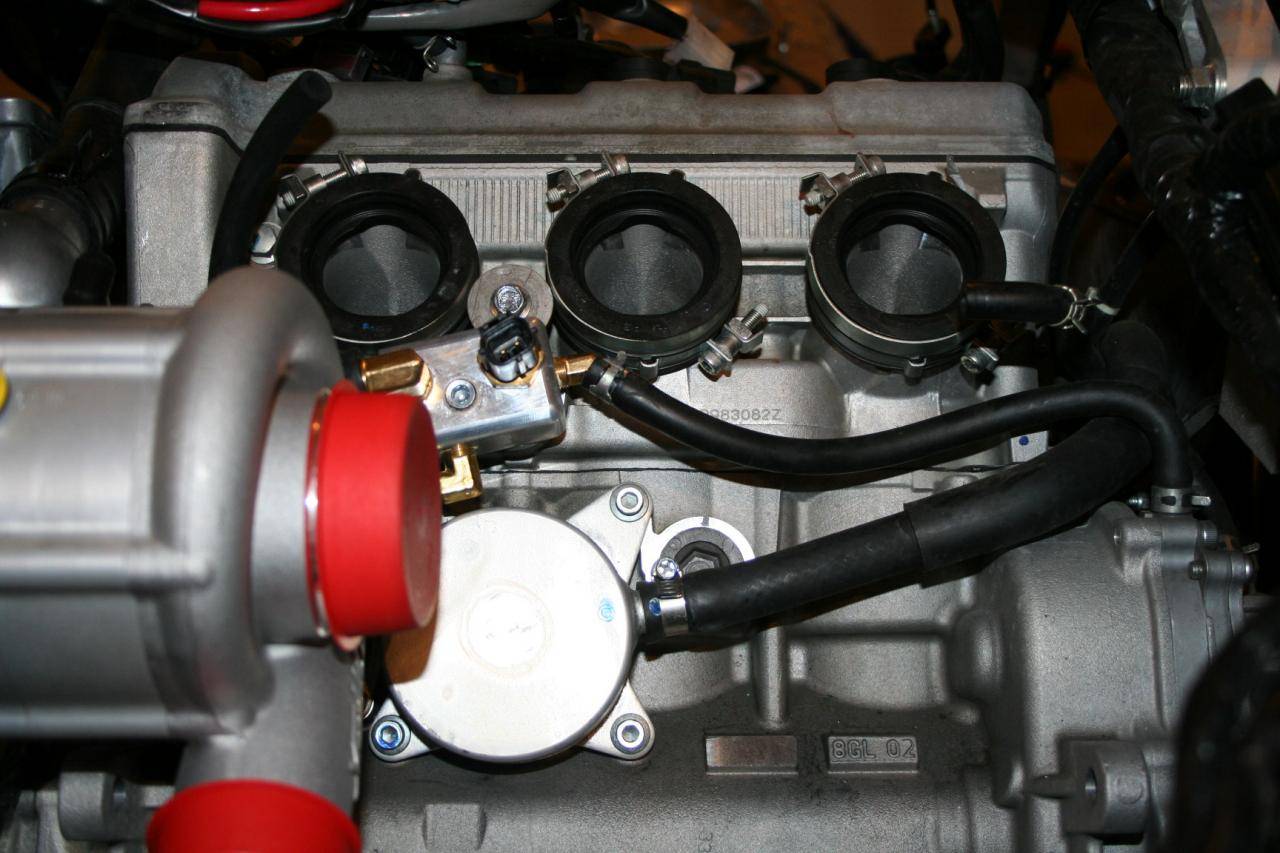

69. Tighten the throttle body to manifold clamps. Install the LH carb heater line. Do NOT remove the OE spacers in the clamps! They tighten fine with the spacers and over tightening will cause problems. See Figure 43.

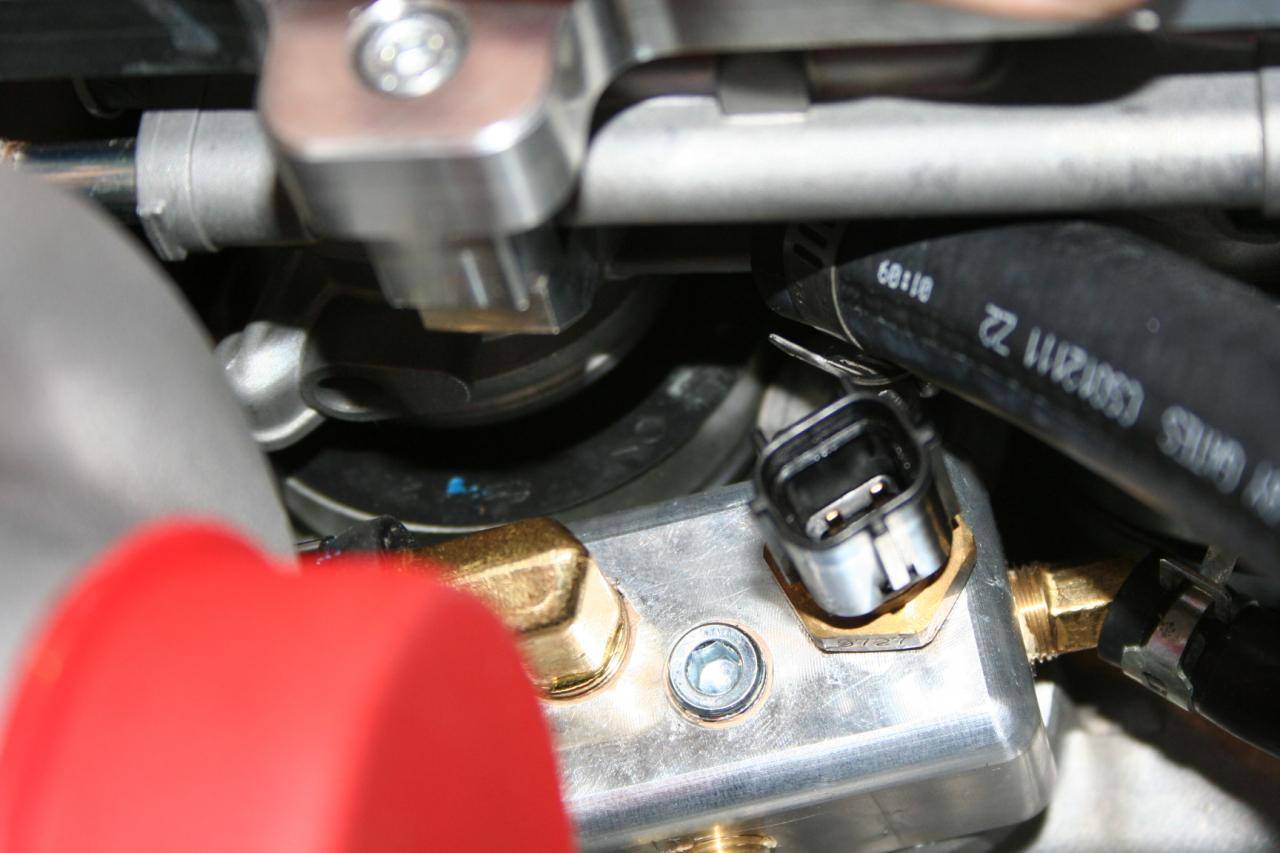

70. Connect the water sending unit wires to the sending unit. See Figure 44.

Back in place using the OEM Clamp.

A view from the other side of the engine showing just how TIGHT all of the hoses are now.

Reconnecting the Thermostat sending wire.

\

\

The Finished Result.

70. Connect the water sending unit wires to the sending unit. See Figure 44.

Back in place using the OEM Clamp.

A view from the other side of the engine showing just how TIGHT all of the hoses are now.

Reconnecting the Thermostat sending wire.

The Finished Result.

SUPERCHARGER OIL SYSTEM – 1st Half

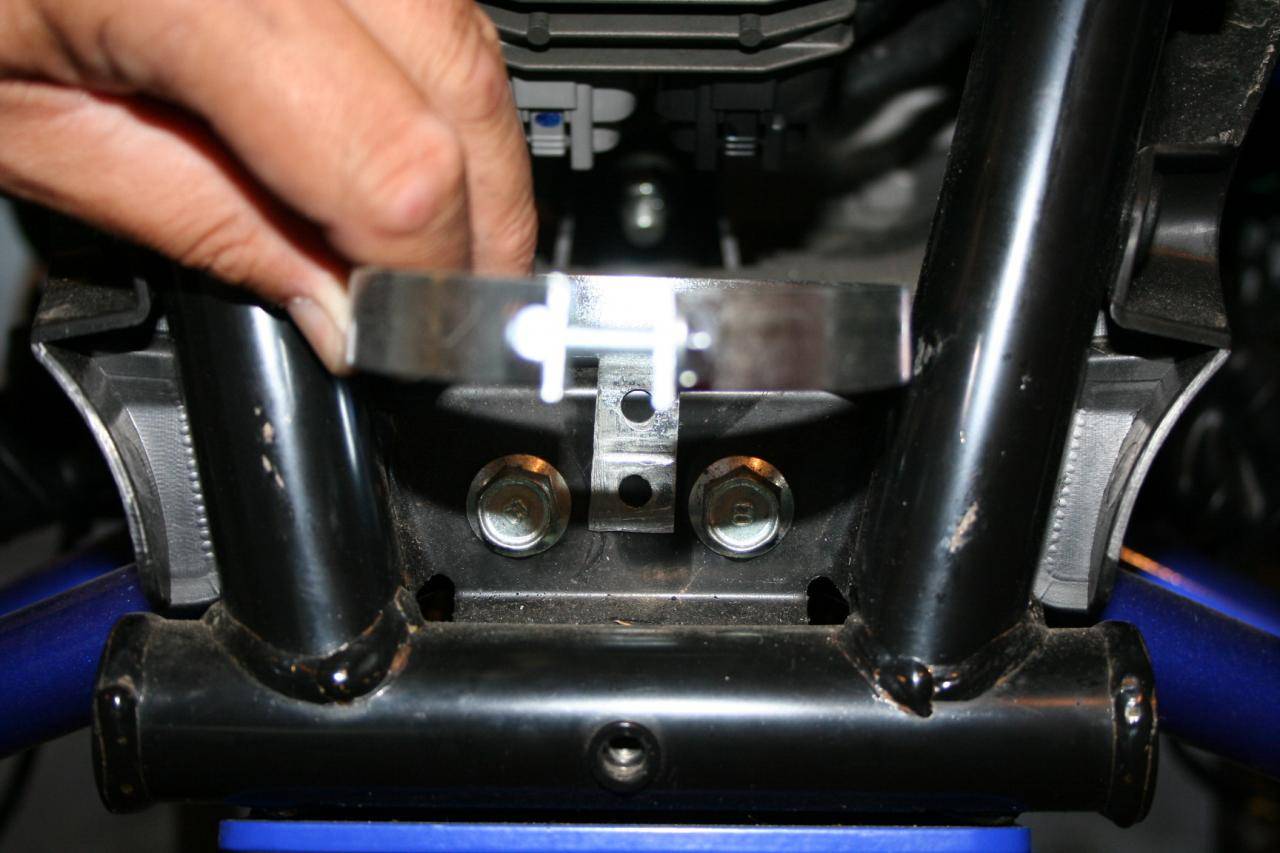

71. Use the Oil tank bracket as a template to mark 2 holes in the lower center frame (between the 2 A-arm bolts). You should mount the bracket as high as possible. The marks in the figure are a little low. Use a 3/16 drill and mount the bottom bracket with 2 rivets provided. Note the orientation of the bracket. See Figure 45.

Holding the bracket in position so I could mark where to drill.

Have center punch will travel.

Drilled it as HIGH and close to the curve as I could

Set the Rivet and the lower bracket is mounted.

71. Use the Oil tank bracket as a template to mark 2 holes in the lower center frame (between the 2 A-arm bolts). You should mount the bracket as high as possible. The marks in the figure are a little low. Use a 3/16 drill and mount the bottom bracket with 2 rivets provided. Note the orientation of the bracket. See Figure 45.

Holding the bracket in position so I could mark where to drill.

Have center punch will travel.

Drilled it as HIGH and close to the curve as I could

Set the Rivet and the lower bracket is mounted.

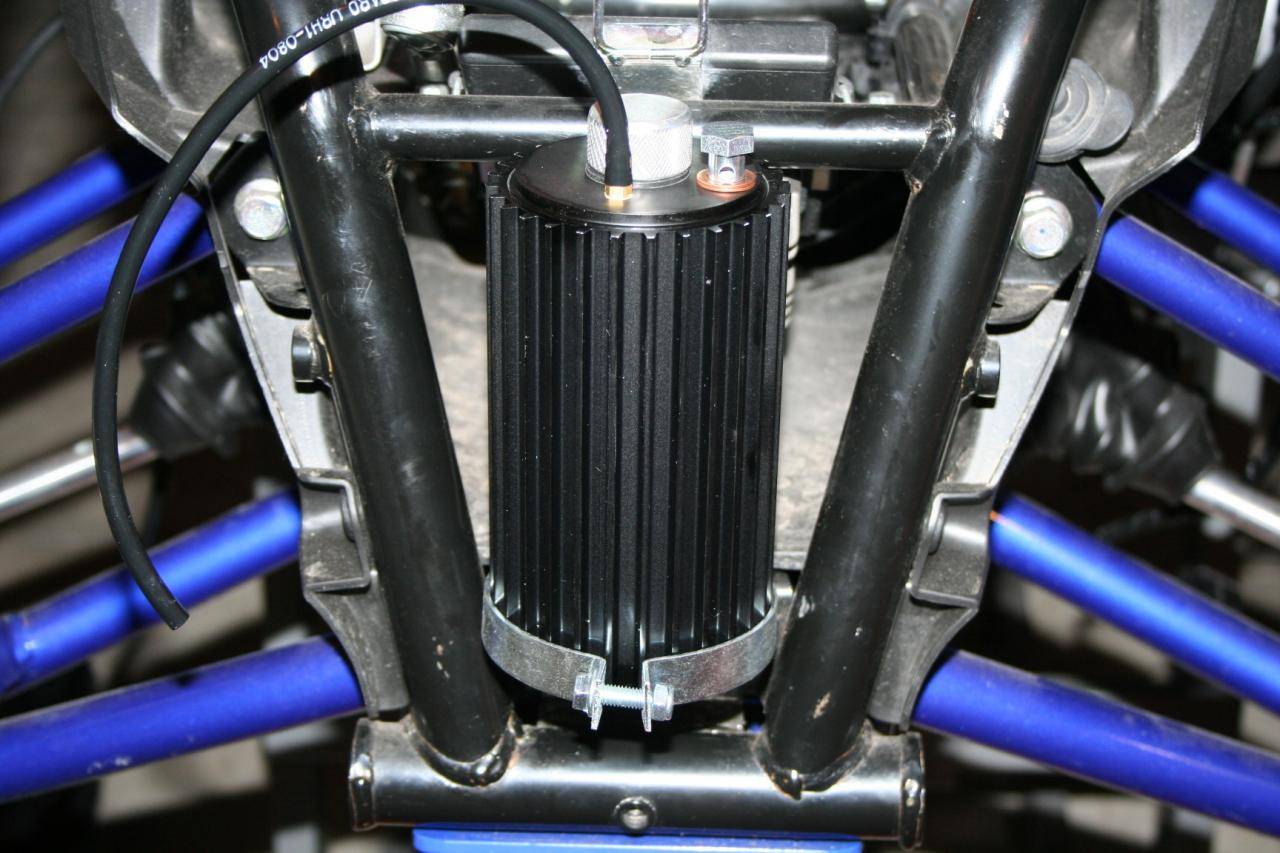

72. Again, using an oil tank bracket as a template mark the lower bracket hole in the top tubular cross member. Install 1 rivet. Now, bend the bracket’s mounting tab around the cross member and install a second rivet in the top hole. See Figure 46.

Test fitting the canister so I could position the upper bracket.

Test fitting the canister so I could position the upper bracket.

74. Route the small oil tank vent line over the top of the Yamaha ECU and secure it with 2 zip-ties. THE PLACEMENT OF THIS OIL LINE IS CRITICAL.

THE END OF THE HOSE NEEDS TO BE LOWER THAN THE OIL TANK ITSELF TO PRESERVE OIL INCASE THE VEHICLE IS FLIPPED OVER.

ADDITIONALLY AND EVEN MORE IMPORTANTLY, THE END OF THE VENT LINE CAN NEVER SIT IN SNOW OR ICE.

IF IT WERE ALLOWED TO IT COULD SUCK WATER INTO THE OIL WHICH WILL CAUSE UNWARRANTABLE AND PERMANENT DAMAGE TO THE SUPERCHARGER.

See Figure 48.

THE END OF THE HOSE NEEDS TO BE LOWER THAN THE OIL TANK ITSELF TO PRESERVE OIL INCASE THE VEHICLE IS FLIPPED OVER.

ADDITIONALLY AND EVEN MORE IMPORTANTLY, THE END OF THE VENT LINE CAN NEVER SIT IN SNOW OR ICE.

IF IT WERE ALLOWED TO IT COULD SUCK WATER INTO THE OIL WHICH WILL CAUSE UNWARRANTABLE AND PERMANENT DAMAGE TO THE SUPERCHARGER.

See Figure 48.

W

Nice job Chris...

A

IF IT WERE ALLOWED TO IT COULD SUCK WATER INTO THE OIL WHICH WILL CAUSE[/U] UNWARRANTABLE AND PERMANENT DAMAGE TO THE SUPERCHARGER.

Been there done that. When the oil cools your vent line becomes a nice little vacuum. Slurp slurp...water in the blower oil means the dumb end of a tow rope and big bucks.

Similar threads

- Replies

- 3

- Views

- 8K

- Replies

- 79

- Views

- 27K

S

- Replies

- 0

- Views

- 3K

S

- Replies

- 13

- Views

- 12K

S