This last weekend I was out west at Laramie (8,000-10,000). I had just added SLP MTX 65g weights and a 13.6 Power Addiction head to my 12 800 163 before we left. I started out with 2 grams in the belly and 1 gram in the tip. Previously before I added the head and weights I was running 10-60s out there and hitting 8,000 pretty repeatedly. The first day I would normally see a high of 7700-7800 while climbing. So I figured the next day I would try it without some of the rivets in the weights. I removed both the 2 grams in the belly and the 1 gram in the tip and just ran them empty. That second day then I would start out hitting 8,000-8100 while climbing but it would quickly fade to as low as 7200 usually being around 7500 though. I had cleaned the clutches before this last trip. The belt is still the original with only 500 miles on it. The only thing I really see on it though is 5" of cord missing on one side but its been like that for 250 miles.

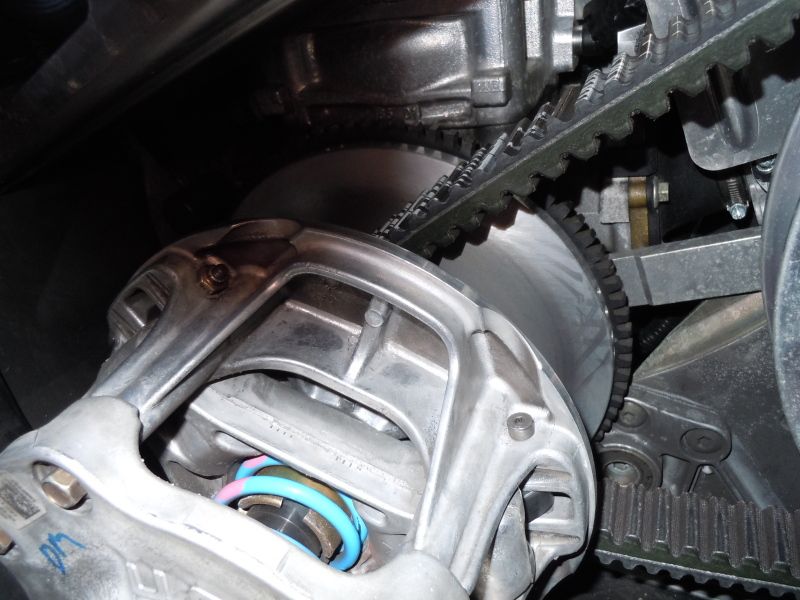

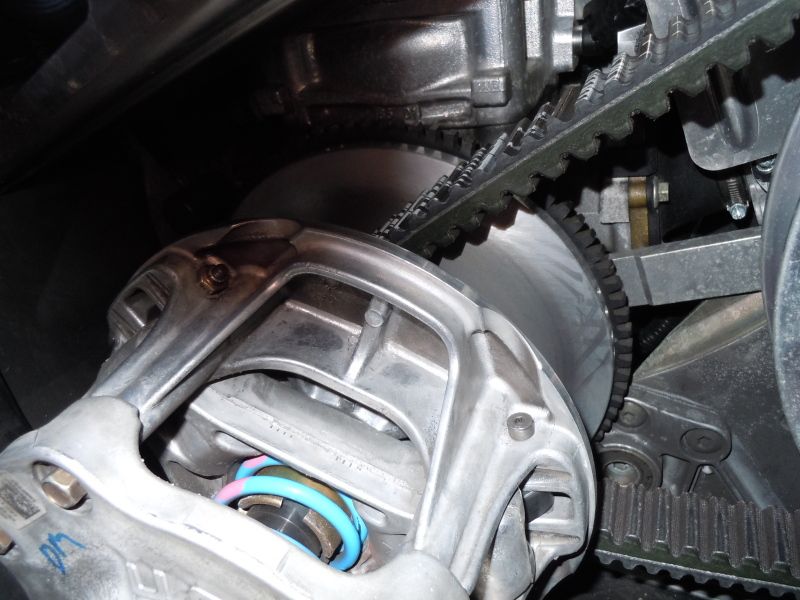

My clutch set up so far includes slp mtx 65 gram weights and the slp blue/pink spring in the primary- which is electric start.

The secondary has the polaris black/purple spring with 1 delrin washer in it.

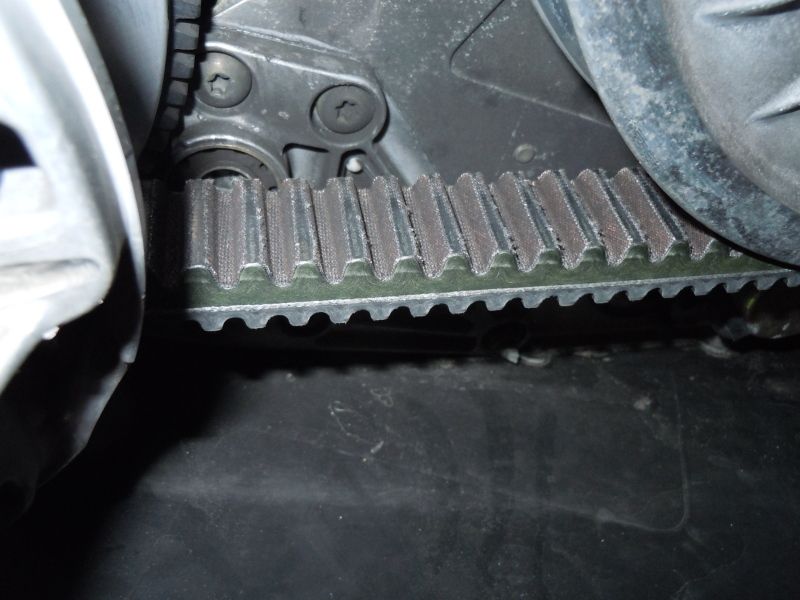

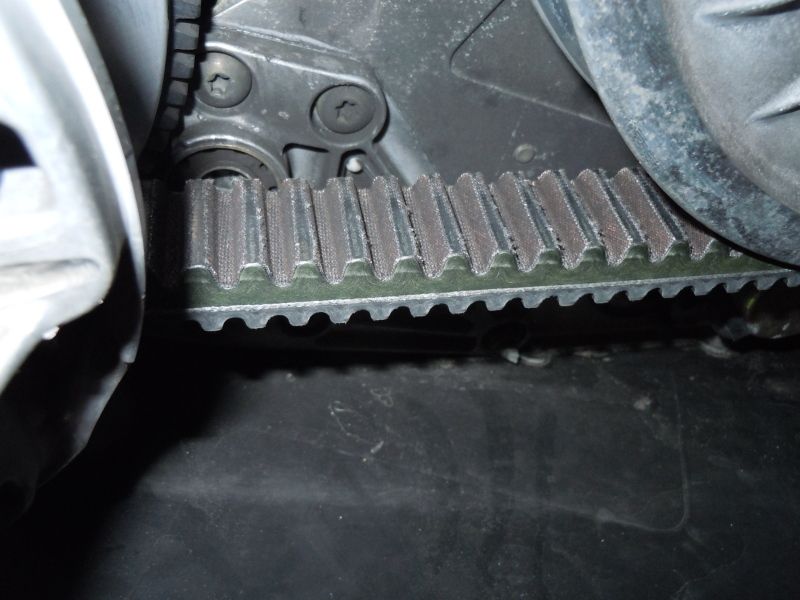

Any ideas on what I should look for to keep the rpm at 8000? Heres a couple pics of my clutches and belt.

My clutch set up so far includes slp mtx 65 gram weights and the slp blue/pink spring in the primary- which is electric start.

The secondary has the polaris black/purple spring with 1 delrin washer in it.

Any ideas on what I should look for to keep the rpm at 8000? Heres a couple pics of my clutches and belt.