I also installed a MTNTK blowhole, and Fire n Ice QD belt tensioner for this year, while not directly related to a top end rebuild... there is a convenience factor so I'll touch on the subject.

While you have the sled 1/2 apart for a top end rebuild is the perfect time to install the blowhole! To do it right, you need the console, clutch cover, oil bottle, and complete airbox out.

-The blowhole kick-plate is not easy to get in the perfect position, the more room you have the easier the work will be. I drilled out most of the rivets on the bottom of the left fender so I could flex it out of the way.

-An air powered angle drill was a blessing, I could tell a few spots would be awkward with a standard drill.

-Use clamps to sandwich the pieces while drilling / riveting.

-Your oil bottle cap is going to be buried in the side panel vent after installing the blowhole, I drilled my own holes to secure the rear of the clutch cover to the MTNTK kick plate so I could shift in inwards a little bit.

I also did their recommended "adjustment" to the clutch cover described in the instructions, and had to trim more of the vent than they said. It still turned out fine.

-I added a small power switch in the console, and an inline 2a fuse.

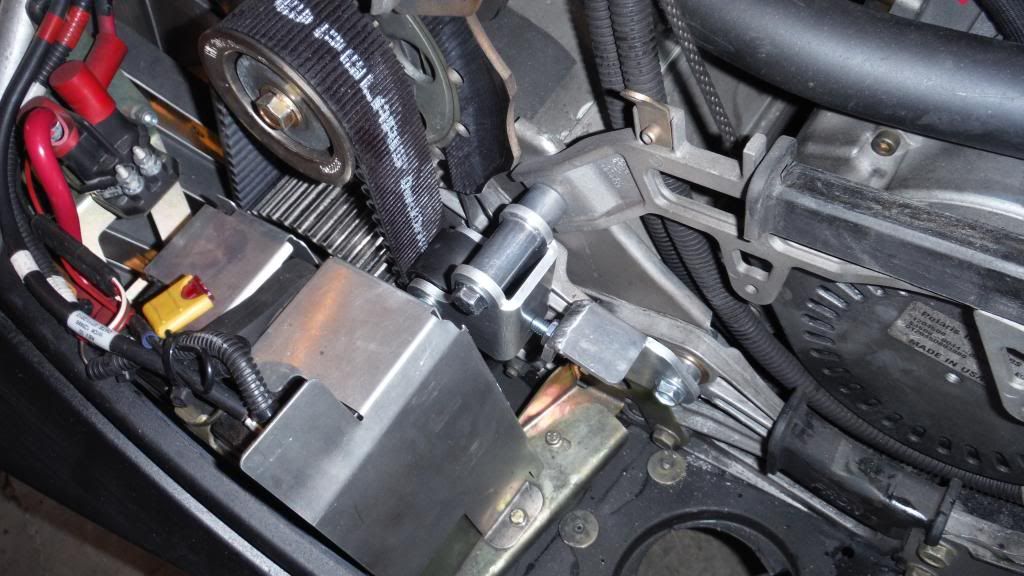

Installing the Fire n Ice QD tensioner is straight forward, good instructions.... but the three torx bolts you have to remove from your chassis are brutal! In the instructions they say that the bolts must be heated, I used a propane torch liberally, and a high quality torx bit to get them out. A cheap bit is only going to cause problems here. They cracked loosed HARD, and then were very stiff to turn out. I didn't pull any threads, but I can see it being a good possibility. There is just more room to deal with this nightmare with the console and exhaust system out of the way.

-If you have e-start like me, you will need to trim a small piece of the back of the tin battery cover so the tensioner doesn't rub / vibrate against it.

And with that... I am done and ready for snow, lets get this s%$# started!