Has any one had a failure with the Zerk in the bottom seen lots of comments on failures with out it but has any one lost the shaft with it. Thanks.

not that I've ever heard of.

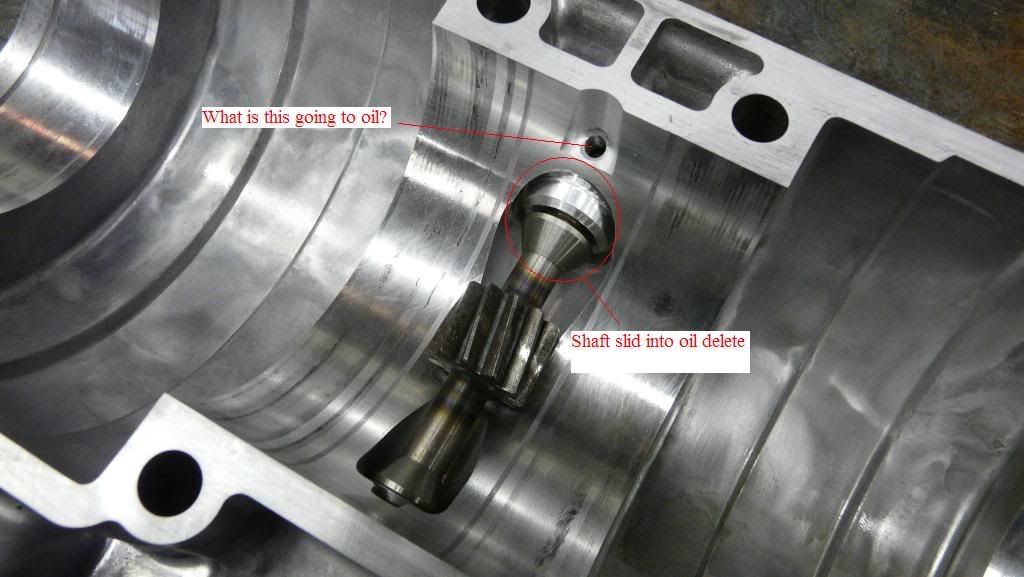

I think drilling where bgreen did is wasteful, (my take) because even in the ones that HAVE failed, I've never heard of it failing there. From what I understand it fails at the back.

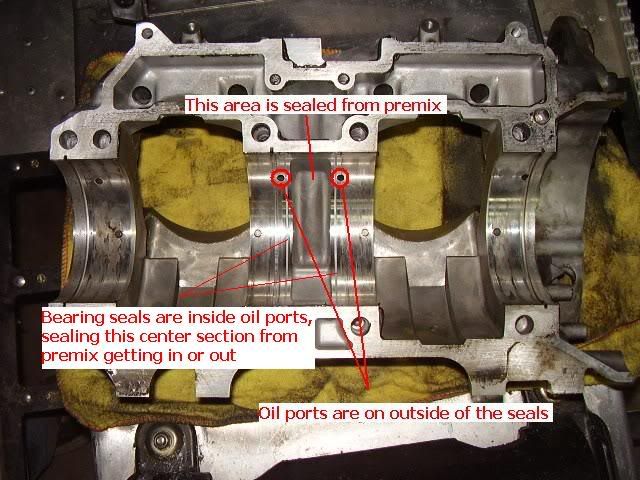

Also if you look at the cases, the lab bearings are pretty tight, but the cases around them aren't. There's a taper on the top 1/2 of the case that when put on top of the bearing, does not seal completely. The oil that was being pumped in there from the stock system NEEDS a way to get out, so obviously this is NOT a sealed area. (some seem to be tighter than others, but none can be COMPLETELY sealed or they'd pop the oil line eventually)

I put grease in at install because I believe that what is failing the few that we've heard about is the initial running after installing the delete dry, I believe it begins it's failure early on when it is run, before any premix can get in there. I feel the ones that didn't fail, are due to there being a bit more oil left in there at the time of install.

I've zerked 4 motors now 3 N/A 1000's & one boosted 8, and know of many more & never heard of a failure.