Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Oil Pump Adjustment

- Thread starter die hard poo

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Thread Rating

- 5.00 star(s)

P

5 threads from the crate , F'n EPA. :face-icon-small-fro

http://i107.photobucket.com/albums/m320/FrontRowpics/2012/sledNov9010.jpg

http://i107.photobucket.com/albums/m320/FrontRowpics/2012/sledNov9010.jpg

Going to get mine broken in first, run a few tanks of gas through it then take some manual readings on usage to see where I'm at..

What is target ratio to shoot for? 32-1? 40-1?

G.

I've heard of people who've dyno'd differnt oil ratios.

Controlled ALL other variables.

Same engine, same oil, same conditions...etc.

That particular set of tests revealed the best HP and torque at an amazing 16:1 mixture.

I can't remember where that was published...but I do remember reading that one.

R

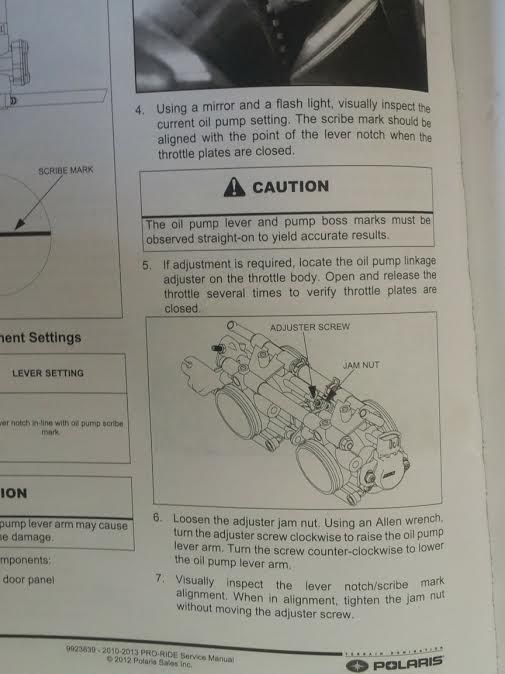

TTT, best oil pump adjustment post yet, thanks MUCH!!!Hey guys, I decided to increase the oil pump flow rate while I had the pro torn down for other projects.

It is kind of a chore to get to, but easy to adjust once you get access.

So in order to get to the adjuster easily you must:

Remove side panels, hood, and rear plastic cover

Remove seat

Remove Gas tank

Remove air-box(which is tight to get out!)

-I had the Oil tank, clutch cover, and clutches off to get the most access, but you might be able to get to it without taking out those parts.

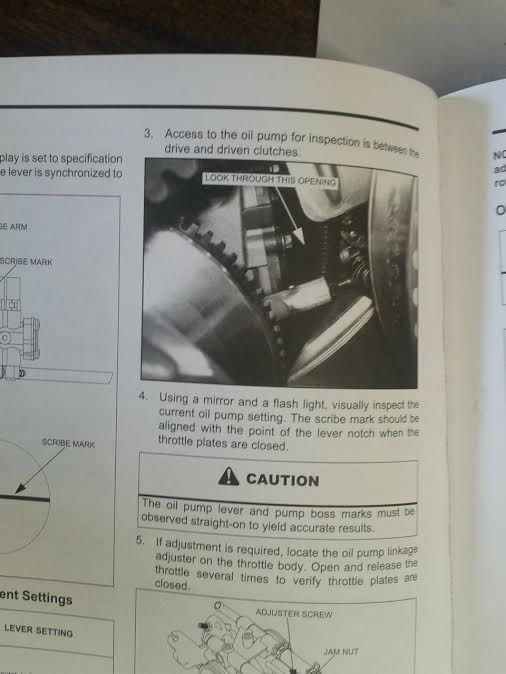

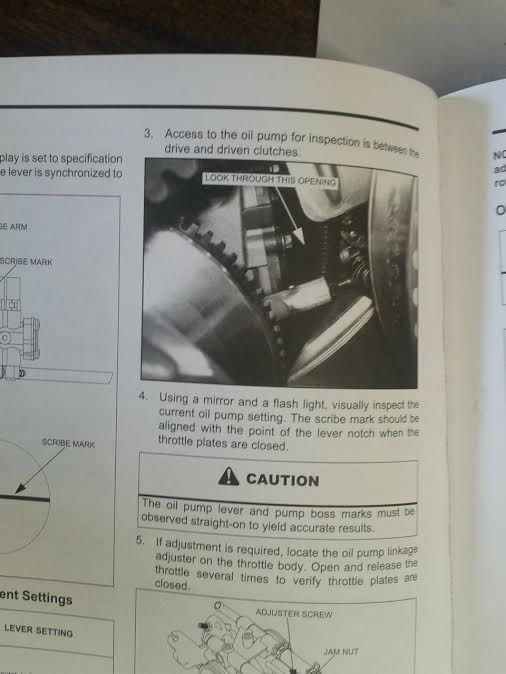

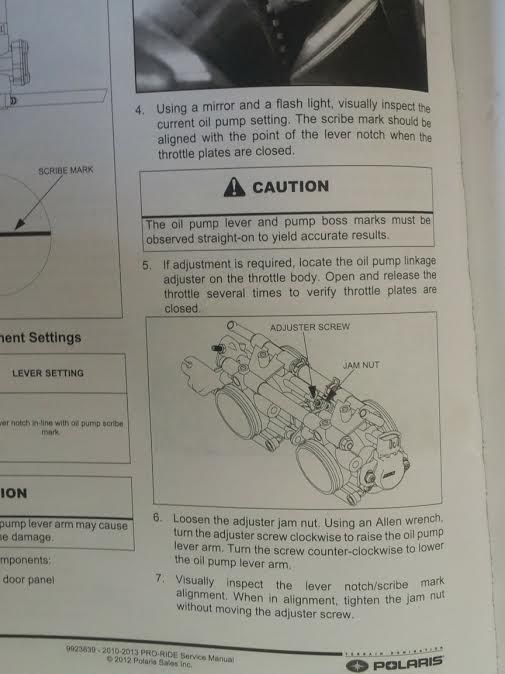

Once all that is out of your way, you will need to screw IN (Clockwise, right tightly) the set screw on the throttle body linkage shown here:

It takes a 8mm (or a 10mm, cant remember lol) to loosen the back up nut and then a flat blade to screw in. You have to push the linkage down like this to adjust it:

This is what it looks like normally

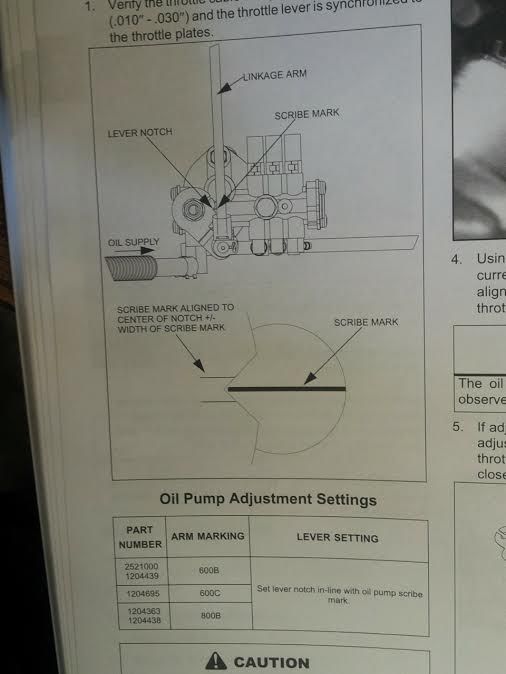

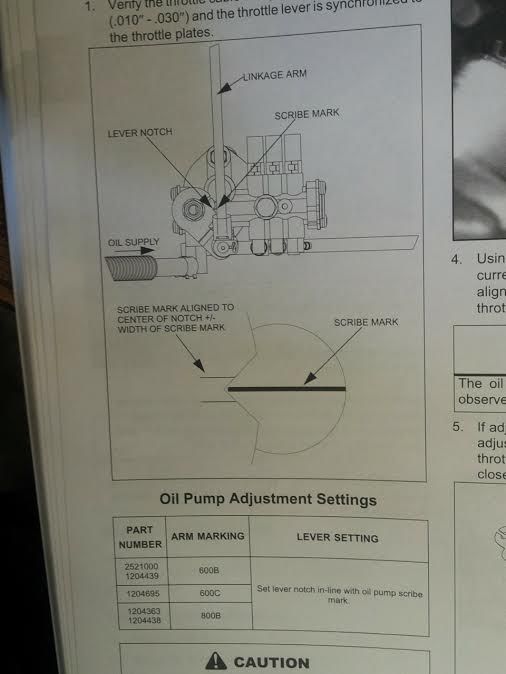

One thing to note is that the oil pump arm set indication is kind of hard to read compared to older Polaris pumps. This is due to the indication arrow being inverted rather than extroverted. So lining up the arrow to the line on the pump's body is harder to see, especially through the little space between the throttle bodies.

Hope this helps!

So if you/we adjust the pump to a desired ratio of 32:1.

And measure the oil consumption from the oil tank.

How much of the oil from the tank is going to the bottom end.

And how does that affect the ratio?

Just sayin/ maybe there's a better way to accurately measure?

or just turn it up 3-5 turns and hope for the best!

And measure the oil consumption from the oil tank.

How much of the oil from the tank is going to the bottom end.

And how does that affect the ratio?

Just sayin/ maybe there's a better way to accurately measure?

or just turn it up 3-5 turns and hope for the best!

No, u don't have to pull the sled that far down, I just happen to be tore down that far for other reasons. (Sorry for the misleading info) Yes just have the hood and panels off and reach it from the top with a 8mm and a long extension and a wobbily. I like to pull the can to see the oil pump adjustment arm easier... Hope that helps.

I'm still trying to get over the fact that you have pull the sled apart that far to adjust the oil pump.

I can see pulling the hood, panels, and airbox.

But the dash shroud, seat AND tank? REALLY??

I would suggest doing it that way the first time (if you even make multiple adjst). Just a lot easier that way to see and help visualize whst ur actuslly doin. After that, youll be confident and be sble to understand what it is exactly youre doing.

Besides, it will give u something to do with that 6 pack on some evening!

Edit: Sorry for fat thumb syndrome... Dang smart phones anyhow!

Last edited:

No, u don't have to pull the sled that far down, I just happen to be tore down that far for other reasons. (Sorry for the misleading info) Yes just have the hood and panels off and reach it from the top with a 8mm and a long extension and a wobbily. I like to pull the can to see the oil pump adjustment arm easier... Hope that helps.

X2, just did this to my cousin's sled today. 8mm socket, swivel adapter, long extension.

Remove hood, Loosen nut with socket, loosen nut almost to top, then with a flat screwdriver, turn in until snug, then tighten 8mm nut. Done.

M

What bad effects will take place if the oil pump is turned right up. No threads showing. Besides hurting the wallet.

I turn them up to where the top of the threads are flush with the nut.

Bump

.

.

I just purchased a 14 carry over and have it torn down some right now. I decided I would check the oil pump screw. Well, based on what I have read and seen (posted Pics) I adjusted my set screw 4 turns. My Set Screw was set at 7.5+ turns out from flush with the nut. So, I have around 3.5 turns left until flush with the nut. I checked the scribe mark with the "v" cut out and I am 3/4the way down the bottom "arm" of the "v".

I would rather burn more oil then not enough. I also disagree that this is progressive. You can clearly see that as more air/fuel are added the pump is "opened" comparatively to the throttle (added air/fuel). So I don't believe the ratio changes as you move throughout the RPM range. More fuel = more oil, but I don't believe it changes the ratio.

Very easy to adjust as well. A guy could do it on the hill, that easy.

Just my opinion and observation.

I will check the ratio once the snow flies and adjust accordingly (around 40:1).

I would rather burn more oil then not enough. I also disagree that this is progressive. You can clearly see that as more air/fuel are added the pump is "opened" comparatively to the throttle (added air/fuel). So I don't believe the ratio changes as you move throughout the RPM range. More fuel = more oil, but I don't believe it changes the ratio.

Very easy to adjust as well. A guy could do it on the hill, that easy.

Just my opinion and observation.

I will check the ratio once the snow flies and adjust accordingly (around 40:1).

I suppose that I could be wrong about this but adding oil to the fuel should still lubricate the crank bearings since the mixture goes into the crankcase and is pushed into the combustion chamber through the transfer ports. Are the crank bearings sealed and lubricated independently on these engines? I don't think that is the case but I don't know for sure. Anybody who is more schooled than me on this engine want to weigh in? Either way, I am not touching my 13 or adding oil. My sled runs great and I have a four year warranty. Not messing with it because it is good. I check the plugs periodically and I can detect no lean conditions.

D

I wont disagree with the "if it aint broke don't fix it" however if it does go down you will be done riding for a few months while it's all being sorted out. Its all about a little insurance for your play time.

As for the idea that the bearings will lubricate properly via the fuel/oil mix only is not the case with a stock motor. The outer bearings get oil directly from the pump and the oil flows through those bearing on the way to the main part of the crank case were it mix's with the fuel. The added lubrication is important. As for my personal opinion the piston to wall clearance is to large on the stock motors. This is done to prevent those who cant wait for the sled to warm up from seizing a piston on cold take offs. Then in my opinion to prevent smoke and emissions from being visible, the oil is turned down to help this issue. Most likely EPA or some government agency.

So adding a small amount of oil to the fuel tank helps to lubricate the piston and upper end of the motor and the added oil from the pump covers the bearings and adds to the overall oiling. 50:1 is a safe mix ratio. Check you fuel burn against your oil consumption and see what ratio you are at.

My 2012 was 89:1 and my 2011 was 78:1 it ran 400 miles before I corrected it. The 2012 went down with a bad crank and a cracked piston skirt at 2000 miles. You never know.....you maybe the lucky guys who never have an issue.

As for the idea that the bearings will lubricate properly via the fuel/oil mix only is not the case with a stock motor. The outer bearings get oil directly from the pump and the oil flows through those bearing on the way to the main part of the crank case were it mix's with the fuel. The added lubrication is important. As for my personal opinion the piston to wall clearance is to large on the stock motors. This is done to prevent those who cant wait for the sled to warm up from seizing a piston on cold take offs. Then in my opinion to prevent smoke and emissions from being visible, the oil is turned down to help this issue. Most likely EPA or some government agency.

So adding a small amount of oil to the fuel tank helps to lubricate the piston and upper end of the motor and the added oil from the pump covers the bearings and adds to the overall oiling. 50:1 is a safe mix ratio. Check you fuel burn against your oil consumption and see what ratio you are at.

My 2012 was 89:1 and my 2011 was 78:1 it ran 400 miles before I corrected it. The 2012 went down with a bad crank and a cracked piston skirt at 2000 miles. You never know.....you maybe the lucky guys who never have an issue.

so is the general consensus to turn the screw 3-4 turns?

I just did mine, 3 full turns in. that little bracket twists super easy. it twisted slightly when loosening the jam nut, but when I tightened the jam nut back down, the bracket ended up in the same place as before starting.

Think this is ok?

I just did mine, 3 full turns in. that little bracket twists super easy. it twisted slightly when loosening the jam nut, but when I tightened the jam nut back down, the bracket ended up in the same place as before starting.

Think this is ok?

Last edited:

S

so is the general consensus to turn the screw 3-4 turns?

clockwise (tighter) correct?

yes you turn it in, clockwise, tighter, all of the above. keep the screw driver in the screw if you can, when i spun the nut to back it off with my finger it turned the screw as well, you dont want that for accurate measurement.

so is the general consensus to turn the screw 3-4 turns?

I just did mine, 3 full turns in. that little bracket twists super easy. it twisted slightly when loosening the jam nut, but when I tightened the jam nut back down, the bracket ended up in the same place as before starting.

Think this is ok?

I think you're fine. I've had to remove the air box before just to straighten that bracket.

Found it

For those like me who couldn't figure out where the marks are to see your adjustment, maybe this will help you. It helped me find it !

[URL=http://s177.photobucket.com/user/highvoltage_photo/media/oil1.jpg.html] [/URL]

[/URL]

For those like me who couldn't figure out where the marks are to see your adjustment, maybe this will help you. It helped me find it !

[URL=http://s177.photobucket.com/user/highvoltage_photo/media/oil1.jpg.html]

[/URL]

[/URL]

Similar threads

T

- Replies

- 6

- Views

- 1K

T

- Replies

- 4

- Views

- 2K

P

- Replies

- 10

- Views

- 3K

E

- Replies

- 15

- Views

- 3K

M