Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

garage shop choices

- Thread starter joshkoltes

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dangit ran out of 2x4s I still need some short shelves on the back wall and to deck it all

Needed shelf material so I took apart the dumb wood patio

It revealed a concrete step and walk in perfect condition. These previous owners were idiots. It would have been so much easier and cheaper to do pavers or another pour to extend what they already had

I then realized all the cuts would be no fun with a skill saw and I wouldnt need a mitre saw when I was finished, I found this evolution chop saw that does every thing wood, steel, plastic, with the same blade, perfect

Was kinda hard to cut it all up after seeing the price of it new but whaaaattever

It revealed a concrete step and walk in perfect condition. These previous owners were idiots. It would have been so much easier and cheaper to do pavers or another pour to extend what they already had

I then realized all the cuts would be no fun with a skill saw and I wouldnt need a mitre saw when I was finished, I found this evolution chop saw that does every thing wood, steel, plastic, with the same blade, perfect

Was kinda hard to cut it all up after seeing the price of it new but whaaaattever

Last edited:

Does anyone here know masonry? I think I'm going to do one course of cinder block around the perimeter with a rebar in ever other block. But since I'm by my self its probably going to take more time then the mortar will stay wet. Question is, is there some kind of adhesive I could use instead of mortar? I'm much better at handling caulk! It had to be said!

I'm no Mason but I did watch the National Treasure trilogy a few times! That has got to be similar to staying at a Holiday Inn Express?

Probably Not, anyway.

Unless you are adding the one course to an existing wall or foundation.

IMO there is no need / advantage to mortar as there is nothing to hold them together anyway.

I essentially did the same thing to my Daughters playhouse (roughly the size of your shed) to get the wood up off of the ground, to prevent rot from setting in too early.

Probably Not, anyway.

Unless you are adding the one course to an existing wall or foundation.

IMO there is no need / advantage to mortar as there is nothing to hold them together anyway.

I essentially did the same thing to my Daughters playhouse (roughly the size of your shed) to get the wood up off of the ground, to prevent rot from setting in too early.

https://youtu.be/i7F3C4MsQwE

I saw this but not too keen on having a bright blue row of bricks

Then this looks like what I need but I can find where to buy it

https://youtu.be/-hid3OQ21_M

I saw this but not too keen on having a bright blue row of bricks

Then this looks like what I need but I can find where to buy it

https://youtu.be/-hid3OQ21_M

Going up

Thanks for the garage journal link. I've been on there for a while but can never seem to find what I'm looking for, Maby if I weren't trying to half *** my projects I could find the answer! Ha-ha oh well I really went off the deep end on this project! I decided to just use liquid nails to glue all the brick together cause you know what? F"¢℅ it! Ha-ha! They will serve their purpose no matter how they are stuck there

Here's my stilts I welded up with the worst welder I've ever owned man that took a long time I should have had the neighbor kid hold my breaker from popping every other rod

Then the raise

Then the stilts

Hope the wind dosnt blow it over while I'm at work!

Thanks for the garage journal link. I've been on there for a while but can never seem to find what I'm looking for, Maby if I weren't trying to half *** my projects I could find the answer! Ha-ha oh well I really went off the deep end on this project! I decided to just use liquid nails to glue all the brick together cause you know what? F"¢℅ it! Ha-ha! They will serve their purpose no matter how they are stuck there

Here's my stilts I welded up with the worst welder I've ever owned man that took a long time I should have had the neighbor kid hold my breaker from popping every other rod

Then the raise

Then the stilts

Hope the wind dosnt blow it over while I'm at work!

Surprisingly this isn't as much work as I thought. Good thing I didn't waste money on a mixer instead I'm just using a wheel barrow and narrow spade

You can see all the rebars and all threads sticking up here, oh and this pic shows the one 100 year old block too. Or at least I can say I found it buried under my hundred year old house

22 bags felt like a lot and made my ferd ride like a Cadillac on the way home!

Filling up nicely

You can see all the rebars and all threads sticking up here, oh and this pic shows the one 100 year old block too. Or at least I can say I found it buried under my hundred year old house

22 bags felt like a lot and made my ferd ride like a Cadillac on the way home!

Filling up nicely

Last edited:

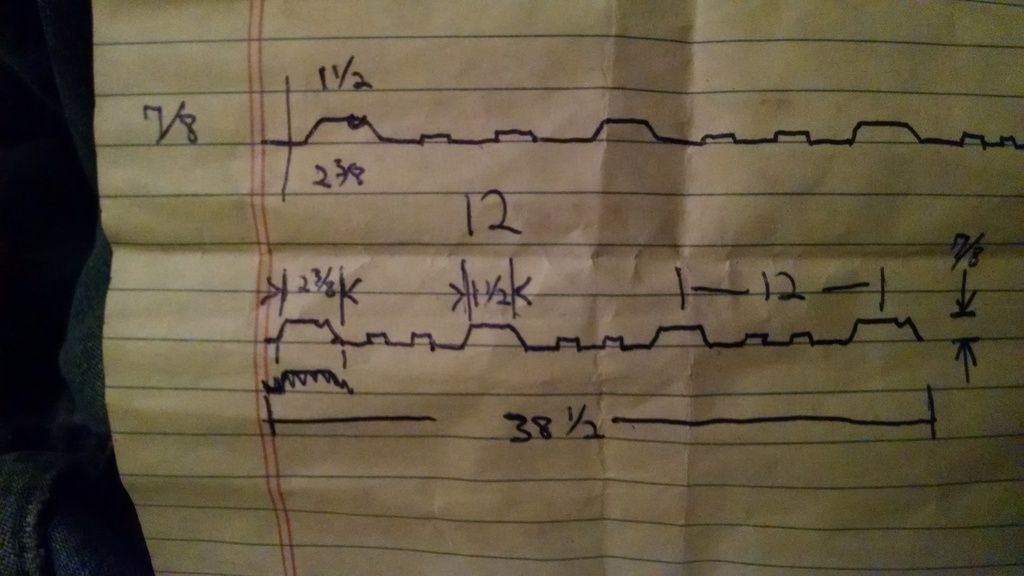

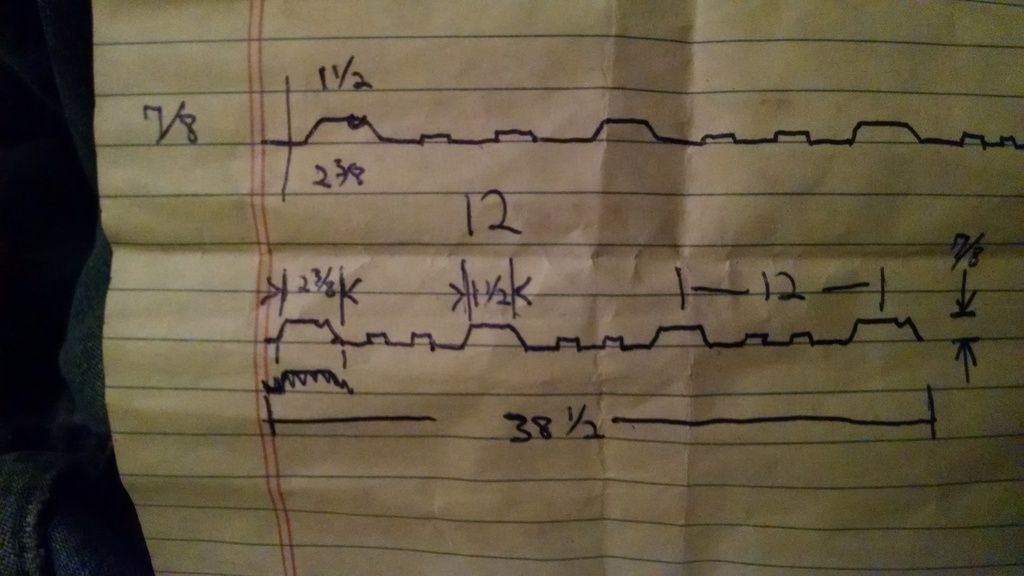

Well I got the new sill plate on and decided to go get some steel panels for the next step. Now I have problems a decisions to make. Turns out this cuckler building went out of business in 1989 and must have had their own specific steel pattern. I could not find this design anywhere around town nor find any help on the matter.

I found a sort of similar panel called an r panel but its 3/8 taller on the rib. It's also narrower so possibly I could just squish it under what I have but then the overall panel will be wider too.

I found a sort of similar panel called an r panel but its 3/8 taller on the rib. It's also narrower so possibly I could just squish it under what I have but then the overall panel will be wider too.

Another option would be a Wayne's coating I think it's called where I put a seam in under the old panels with a track and just go with a different style panel. This would require a little more wood working to have a place to fasten all the necessary seam components to. The end result might look a bit goofy too. Being the standard steel sizes are now spaced nine inches on the ribs instead of the twelve inches that I have.

I wonder if I could find aa flat flashing of some sort to fill the hole, well I guess ply wood would work there too

I found a sort of similar panel called an r panel but its 3/8 taller on the rib. It's also narrower so possibly I could just squish it under what I have but then the overall panel will be wider too.

I found a sort of similar panel called an r panel but its 3/8 taller on the rib. It's also narrower so possibly I could just squish it under what I have but then the overall panel will be wider too.Another option would be a Wayne's coating I think it's called where I put a seam in under the old panels with a track and just go with a different style panel. This would require a little more wood working to have a place to fasten all the necessary seam components to. The end result might look a bit goofy too. Being the standard steel sizes are now spaced nine inches on the ribs instead of the twelve inches that I have.

I wonder if I could find aa flat flashing of some sort to fill the hole, well I guess ply wood would work there too

You could do the wainscoting and just run the ribs parallel to the ground. Or do some other type of veneer panel like fake brick or stone.

Sent from my SM-G900V using Tapatalk

Sent from my SM-G900V using Tapatalk

Last edited:

Yeah that stone looks pretty nice! I'll have to price that out.

I thought about running panel horizontal but it would look goofy

I had a friend suggest something similar to that stone panel,

http://m.homedepot.com/p/James-Hard...nt-Sierra-8-Vertical-Siding-617863/202035428/

Not as fancy but more cost effective, same idea though. This cement panel over some plywood, still might look a bit strange. Your stone look looks like its supposed to be there

I thought about running panel horizontal but it would look goofy

I had a friend suggest something similar to that stone panel,

http://m.homedepot.com/p/James-Hard...nt-Sierra-8-Vertical-Siding-617863/202035428/

Not as fancy but more cost effective, same idea though. This cement panel over some plywood, still might look a bit strange. Your stone look looks like its supposed to be there

That might work!

I figured out a better way though!

I'm going to replace all the sheeting off one wall with something similar but not exactly the same. That wall won't have any short seams that way. Then all the sheets I took off can be used for the short sheets around the rest of the building! Hoorayy

I figured out a better way though!

I'm going to replace all the sheeting off one wall with something similar but not exactly the same. That wall won't have any short seams that way. Then all the sheets I took off can be used for the short sheets around the rest of the building! Hoorayy

It's guys like you that make guys like me look bad. You are quite the handyman!

Similar threads

B

- Replies

- 8

- Views

- 3K

B

M

- Replies

- 2

- Views

- 603

C

B

- Replies

- 2

- Views

- 671

V

B

- Replies

- 7

- Views

- 2K

B