To all the post I said I never had a problem, this is a direct result of the bdx oil delete. Just letting you know.

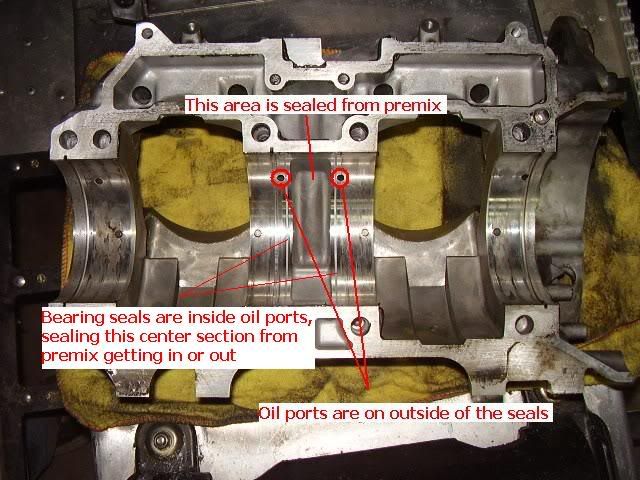

Put it in to there specification, no added oil tube or way get the required amount of lube to center of crank and it dried out center crank bearing and locked them up. Kinda BS. I figured they would know best and would have givin the info needed to do it right but guess not. Even though in the long run its my fault.

Sure liked the way it ran with the oil delete (till Now) But

The other thing that pi$$es me off is the fact I had to put it on because the AC oil injection was sticking and making my sled bog. with it off in my hand I can feel it sticking in the middle and can actually set it in the middle stuck.

BS call to AC on that one.

I ussually ran the sled fat on bottom to make sure it got plenty of oil but recently added a PCIII with the slp programing and it cleaned it up a bunch off bottom and may have caused it but maybe not.

You have been informed, don't be dumb like me. add a way to get oil to the center of crank.

Put it in to there specification, no added oil tube or way get the required amount of lube to center of crank and it dried out center crank bearing and locked them up. Kinda BS. I figured they would know best and would have givin the info needed to do it right but guess not. Even though in the long run its my fault.

Sure liked the way it ran with the oil delete (till Now) But

The other thing that pi$$es me off is the fact I had to put it on because the AC oil injection was sticking and making my sled bog. with it off in my hand I can feel it sticking in the middle and can actually set it in the middle stuck.

BS call to AC on that one.

I ussually ran the sled fat on bottom to make sure it got plenty of oil but recently added a PCIII with the slp programing and it cleaned it up a bunch off bottom and may have caused it but maybe not.

You have been informed, don't be dumb like me. add a way to get oil to the center of crank.