S

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: this_feature_currently_may_not_be_available_in_some_browsers

Another NyPro Project

- Thread starter sportsterdanne

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

S

S

J

Looking good! With one of my tanks I had problems with the fuel pickups flipping forward and getting stuck straight up in the air. Might be a good idea to make that long center hose more rigid some how

S

Thanks !

Are you making any progress ?

The hoses i use are pretty stiff, but if it becomes a problem i will look into it.

Are you making any progress ?

The hoses i use are pretty stiff, but if it becomes a problem i will look into it.

Looking good! With one of my tanks I had problems with the fuel pickups flipping forward and getting stuck straight up in the air. Might be a good idea to make that long center hose more rigid some how

S

J

Thanks !

Are you making any progress ?

The hoses i use are pretty stiff, but if it becomes a problem i will look into it.

Not as much as you are!

Kinda went to the back burner when my rails got delayed

S

S

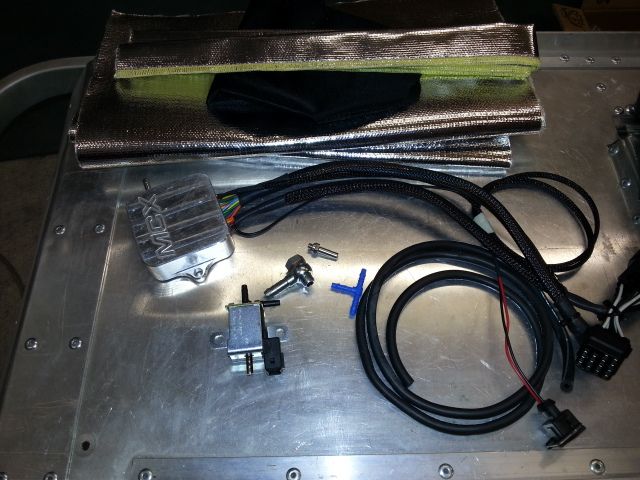

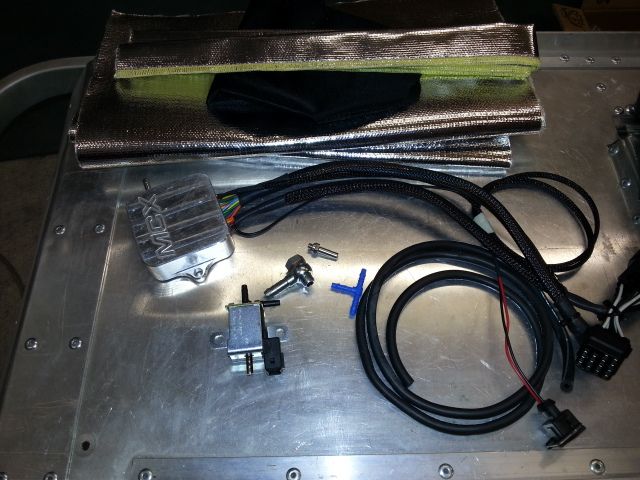

Took a ride to McXpress and got the Gen5 box and a TCV and some other stuff, excellent service from Erik he took time to help me even when he had closed the shop for vacation, he even made me a base map for the Rising rate FPR (a bit different than a stock Nytro)

Found a Place to install the box.

And the TCV.

A short clip of a start (Before i installed the MCX Parts).

http://www.youtube.com/watch?v=5nj9mPIRNeQ

Found a Place to install the box.

And the TCV.

A short clip of a start (Before i installed the MCX Parts).

http://www.youtube.com/watch?v=5nj9mPIRNeQ

S

What led light are you using, and how are they?

im using one of these http://m.aliexpress.com/item/1272504517.html

it is pretty bright but since i installed it a couple of weeks ago i have not tried it when riding.

Last edited:

S

S

S

S

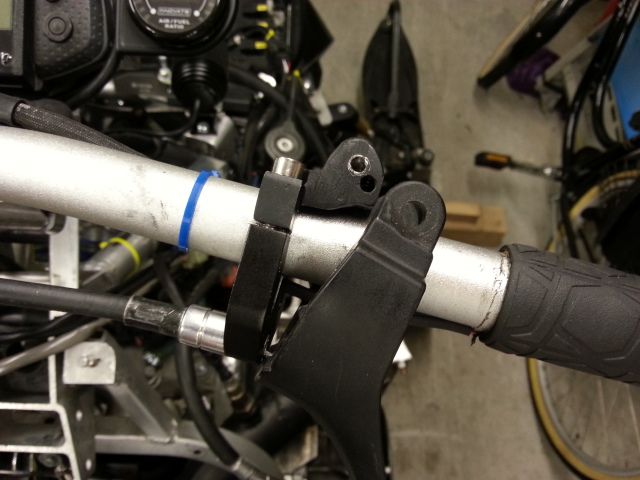

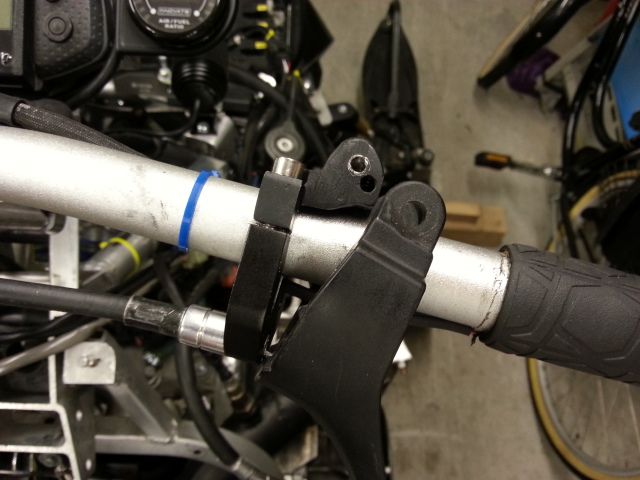

I modified my throttle block, it had the wrong angle for the Yamaha lever, and made i a bit Heavy to pull and at full throttle i had a 1/2" gap to the bar.

Welded some material to it and drilled and tapped after measuring on the stock throttle block

Result.

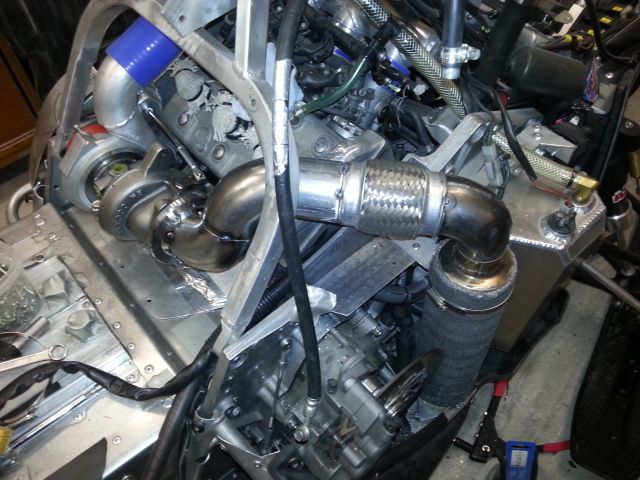

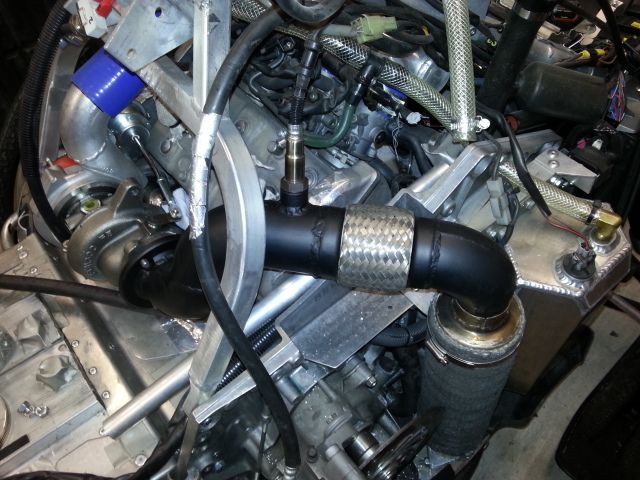

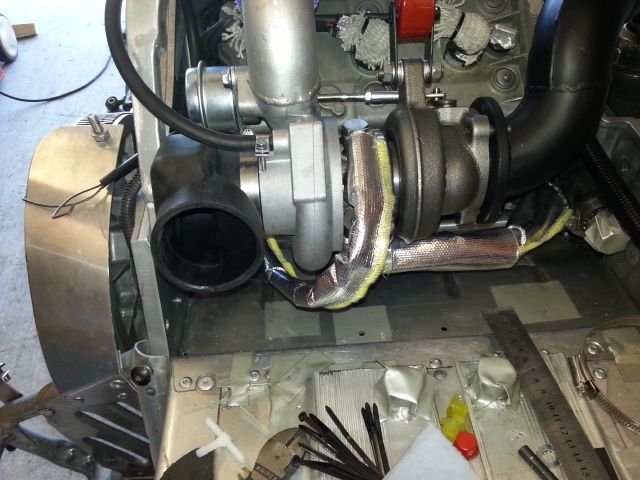

Made a new "hanger" for the turbo since the rubber bushing got to hot and became soft on the first i built.

Added some extra brackets to mount the lower side panels

Welded some material to it and drilled and tapped after measuring on the stock throttle block

Result.

Made a new "hanger" for the turbo since the rubber bushing got to hot and became soft on the first i built.

Added some extra brackets to mount the lower side panels

S

I was not able to get a Dyno run earlier than 3 weeks from now so i decided to start on the tunnel build.

Started by cutting the coolers apart since my tunnel is about a inch wider than a Pro ride.

The first problem was that my sheet is 1,5mm and Polaris seems to be using closer to 1,3mm probably some wierd inch measurement

So i had to make the groove for the sheet bigger i tried some different options but came up with using a 1,5 mm drill as a "mill", it took its time but worked.

Here is the difference in width.

the gap in the cooler cross over tube.

Overview.

This sucks !!

I copied the Pro ride sheet but made it wider, but on the Polaris the sheet is shorter than the coolers and i want it the same lenght.

I could make a small plate to fill the gap but i will make a new sheet 31mm longer since i have material for it.

Started by cutting the coolers apart since my tunnel is about a inch wider than a Pro ride.

The first problem was that my sheet is 1,5mm and Polaris seems to be using closer to 1,3mm probably some wierd inch measurement

So i had to make the groove for the sheet bigger i tried some different options but came up with using a 1,5 mm drill as a "mill", it took its time but worked.

Here is the difference in width.

the gap in the cooler cross over tube.

Overview.

This sucks !!

I copied the Pro ride sheet but made it wider, but on the Polaris the sheet is shorter than the coolers and i want it the same lenght.

I could make a small plate to fill the gap but i will make a new sheet 31mm longer since i have material for it.

S

S

I have decided to make the Dynorun next week anyways, so i will install my old tunnel temporary just to make it easier to transport.

Cut a small piece to the cross over tube.

Then i welded it in Place and added a reinforcement that will double as an extra attachement for the tunnel skin.

I had to grind the welds because the sheet is right on top of the tube.

Pressure tested all welds and they where ok.

I also got my 6,4 mm rivets for the tunnel since the holes in the coolers are a bit big for the standard 4,8 mm rivets

Cut a small piece to the cross over tube.

Then i welded it in Place and added a reinforcement that will double as an extra attachement for the tunnel skin.

I had to grind the welds because the sheet is right on top of the tube.

Pressure tested all welds and they where ok.

I also got my 6,4 mm rivets for the tunnel since the holes in the coolers are a bit big for the standard 4,8 mm rivets

S

Similar threads

T

- Replies

- 1

- Views

- 2K

T

- Replies

- 24

- Views

- 5K

H

- Replies

- 16

- Views

- 2K

C

M

- Replies

- 0

- Views

- 2K

M